In this article, we explained definition of Formwork, different types of formwork used in construction, aluminium, tunnel formwork in construction, Advantages.

Short Summry:

Formwork is a temporary structure that is used to support wet concrete until it hard. Formwork cost is 25 to 30% of the total cost. major 6 types of formwork used in construction. 1. timber formwork, 2. steel formwork, 3.plastic formwork, 4. aluminum formwork, 5. plastic formwork, 6. fabric formwork.

Timber formwork is mostly used in construction for small construction, were steel, and aluminum formwork mostly used for large construction due to its initial cost. plastic formwork is an interlock type formwork, which is also useful for small construction, where fabric formwork is useful for the complex shapes of the concrete members.

Tunnel formwork is a special type of formwork. RCC slab and wall, both are constructed simultaneously by using tunnel formwork. Also, tunnel formwork has a less cycle period.

Table of Contents

What is Formwork in Construction?

When the concrete is tilted, it is in a plastic state, so it needs temporary supports and casing to hold it until it is strong enough. This temporary casing is called Formwork or Form or Shuttering.

- The term mould is used for the formwork of small units like lintels, cornices etc.

- The formwork used for circular works like arch, dome etc. is called centering.

- The shape of the formwork is kept according to the shape of the concrete member. The formwork is properly arranged and filled with concrete.

- Formwork is maintained until the concrete is strong enough to withstand the impacts on it.

Formwork is an expensive item and therefore its proper design and maintenance can lead to considerable cost savings, with construction costing 20 to 25 times the cost of concrete for formwork.

Also Read: What is Modular Construction | Types of Modular Construction

Types of Formwork in construction:

The following types of formwork used in construction.

- Timber formwork

- Steel formwork

- Plywood formwork

- Aluminium formwork

- Plastic formwork

- Fabric formwork

- Tunnel formwork

Precast concrete or fiber glass is also often used for formwork for curves.

1. Timber Formwork

Timber formwork is the oldest type of formwork in construction. It is used in construction from ancient period.

In small construction, timber formwork is mostly used because it is easily usable and it offers an onsite fabrication for the required size and shape of concrete.

But for large construction, timber formwork becomes a time consumptive formwork. As well as timber formwork have less life compare to other formwork.

Timber formwork is cheaper than steel or aluminium formwork when used only For smaller works.

Advantages of Timber Formwork:

The advantages of timber formwork in construction are as follows.

- Its initial cost is low.

- Timber formwork is light in weight and can be easily manipulated.

- More suitable for small works.

- It can be used for anything other than formwork.

- In houses where the size of the room does not change much, the timber cut is less, so the timber formwork is cheaper.

Also Read: How to Construct Diaphragm Wall

2. Steel formwork

Steel formwork is cheaper if the formwork has to be used multiple times.

Steel formwork costs more to start with, but in large works where the formwork has to be used frequently it becomes cheaper, in addition, steel formwork can be easily configured as well as removed.

- This makes the concrete surface smooth.

- Steel formwork for special works such as circular columns, curved surfaces speeds up the work.

- Steel formwork is most popular due to its strength, durability, life and reuses.

Advantages of steel formwork:

Advantages of steel formwork in construction are as follow.

- Steel formwork is more useful when formwork is to be used frequently.

- The initial cost of steel formwork is high. But in large works where formwork has to be used frequently it becomes cheap.

- Steel formwork is easy to apply as well as remove.

- It does not suck water from the concrete, so the surface of the concrete is less likely to be honeycombed.

- It does not change shape or shrink. So gives more accuracy and workmanship compared to timber formwork.

- It can be easily adjusted as well as opened so that labor cost is reduced.

- It gives smooth surface of concrete and does not require re-finishing of concrete surface.

- It has high strength.

- Its durability is much higher than timber formwork.

Also read: Basic Knowledge of Dam Engineering

3. Plywood Formwork

Plywood formwork is updated type of timber formwork in construction. In this formwork plywood is used to support concrete work.

Various Numbers of plywood are attached to make perfect shape and size of concrete work.

Advantages of Plywood Formwork:

The advantages of plywood formwork in construction are as follows.

- It can be used frequently.

- Under normal circumstances timber formwork can be used 10 to 12 times while plywood formwork can be used 20 to 25 times.

- Plywood formwork gives smooth surface of concrete so does not require re-finishing of concrete surface.

- Larger areas can be covered using larger panels, thus reducing labor costs.

Also Read: Modern Partition Wall Design Ideas

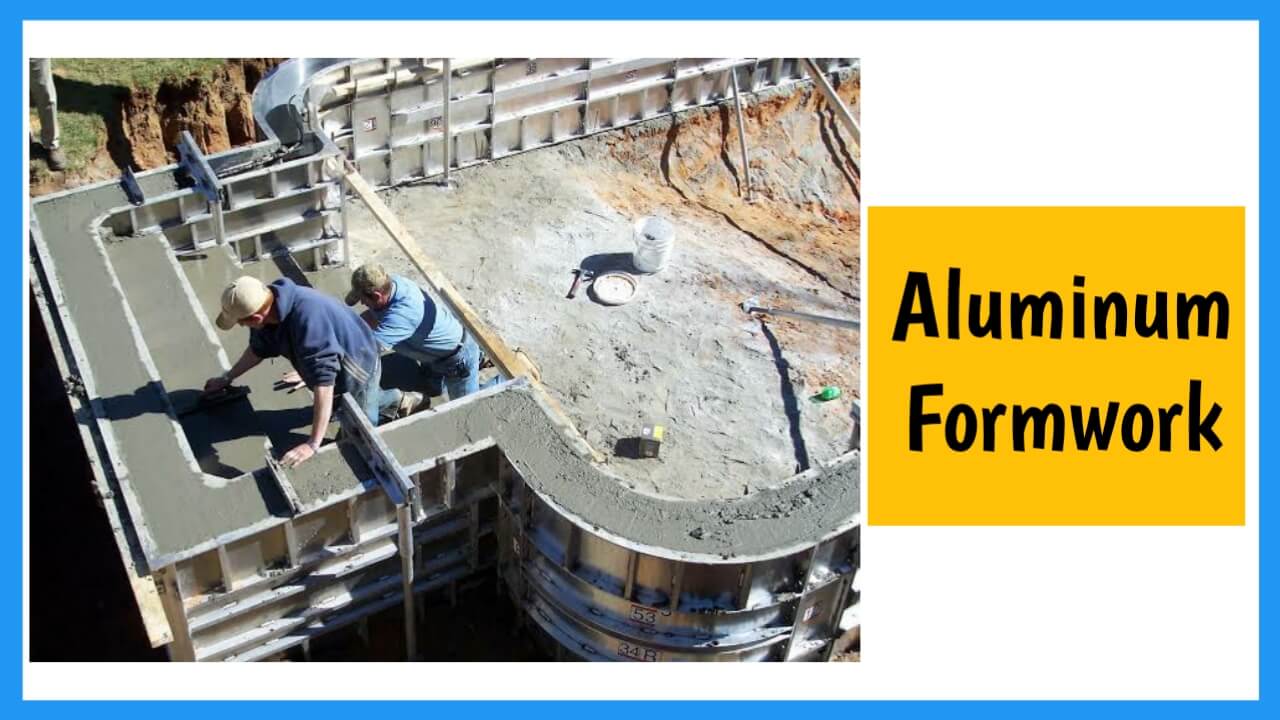

4. Aluminium formwork

Aluminium formwork is also known as mivan shuttering or mivan formwork in construction. It is very similar to steel formwork.

Most of the researches proven that aluminium formwork is economical for large construction compare to other formwork.

Aluminium formwork is very fast, simple and cost effective. It is very cost effective for repetitive building layout.

Aluminium formwork increase the efficiency of work as well as provide a smooth form finish of the concrete, due to that the need of plastering work decreases.

Advantages of aluminium formwork:

Advantages of aluminium formwork in construction are as follow.

- Aluminium formwork is more useful when formwork is to be used frequently and area of construction is a large.

- It is lightweight compare to steel formwork.

- It does not suck water from the concrete, so the surface of the concrete is less likely to be honeycombed.

- Aluminium formwork gives smooth surface of concrete and does not require re-finishing of concrete surface.

- It is Economical for large construction.

Also read: 9 Method of demolition and process for building structures

5. Plastic Formwork

Now a day plastic is also use as a formwork material. Plastic formworks are lightweight consist interlocking system or modular system.

Plastic formworks are best for small constructions which have a repetitive task.

Plastic formworks are easy to clean with water.

Advantages of plastic formwork:

Advantages of plastic formwork in construction are as follow.

- It is lightweight.

- Easy to clean with water.

- Consist a interlocking system due to that size of formwork can be easily adjustable.

- Best for small construction as well as large construction.

- Plastic formwork can be use more than 100 times.

Also Read: What is Monolithic Construction Technology

6. Fabric formwork

Fabric formwork is new advance type of formwork in construction which is specially used for complex shape of concrete member. Due its great flexibility, it make formwork very simple for complex member.

7. Tunnel formwork

Tunnel formwork is a special type of formwork in construction, which is now a day become a most popular for high rise building.

The tunnel formwork is room formwork in which RCC slab and wall are casted in continuous pour. Then hot air blows thermal curing is used to accelerate curing process of concrete. The cycle time for tunnel formwork system is 1-3 days only.

The tunnel formwork system is very useful for repetitive room design.

Requirement of good Formwork:

The requirement of good formwork in construction are as follows.

- Easy removal

- Economy

- Less Leakage

- Rigidity

- Smooth surface

- Strength

- Supports

1. Easy removal

Formwork design should be such so that it can be easily removed by less hammering, so that the damage to the concrete is also less.

If the formwork can be easily removed, it can be reused for a small cost.

2. Economy

Formwork is not useful for stability of finished concrete. So its cost can be reduced by keeping in mind the safety.

The following steps should be taken to bring economy in formwork work.

- Reduce the use of irregular shapes of form.

- Try to keep size of rooms similar.

- Using commercial sizes of formwork available in the market.

- Reuse as soon as the formwork is removed.

3. Less Leakage

The formwork should be such that leakage between its two joints is minimimum.

4. Rigidity

Formwork should be strong enough to retain its shape without excessive deformation. Deflection should not exceed span/300 for open visible surface and for non-visible surface deviation should not exceed span/150.

5. Smooth surface

The surface exposed to the concrete of formwork should be smooth. For which a oil is applied on the inner surface of the formwork.

6. Strength

Formwork should be strong enough to bear the weight of wet concrete as well as concrete filling and equipment, labor, etc.

7. Supports

Formwork should be supported on good, hard and non-flexible supports.

Formwork Removal Time as per IS 456

The removal time of formwork in construction as per IS 456 for OPC and PPC cement is tabulated below.

| Sr. No. | Type of Formwork | For Concrete Made using OPC Cement | For Concrete Made using Cement Other Than OPC or using Mineral Admixture such as Fly Ash, etc. |

|---|---|---|---|

| 1. | Vertical formwork to columns, wall, beams | 16-24 hours | 16-24 hours |

| 2. | Slab ( props left under ) | 3 days | 7 days |

| 3. | Beam soffits ( props left under ) | 7 days | 10 days |

| 4. | Props for Slab | ||

| (a). | Spanning upto 4.5m | 7days | 10days |

| (b). | Spanning over 4.5m | 14days | 14days |

| 5. | Props to Beam and Arches | ||

| (a). | Spanning upto 6m | 14days | 14days |

| (b). | Spanning over 6m | 21days | 21days |

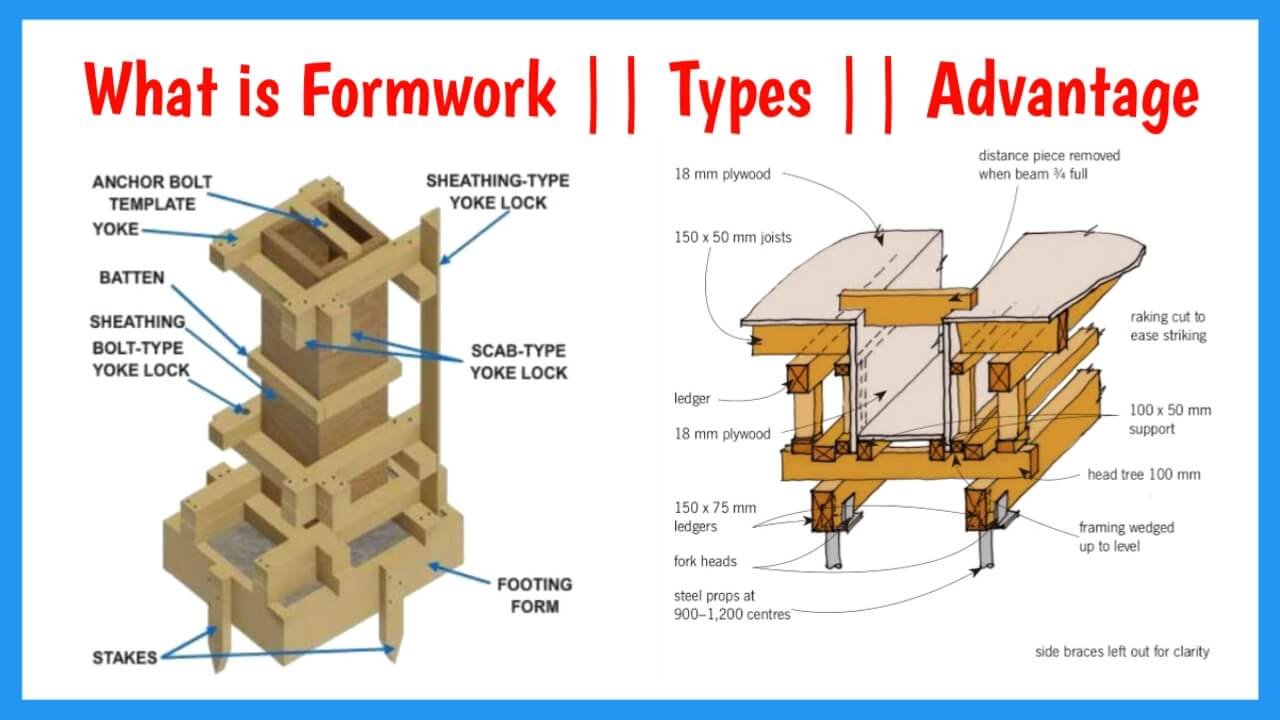

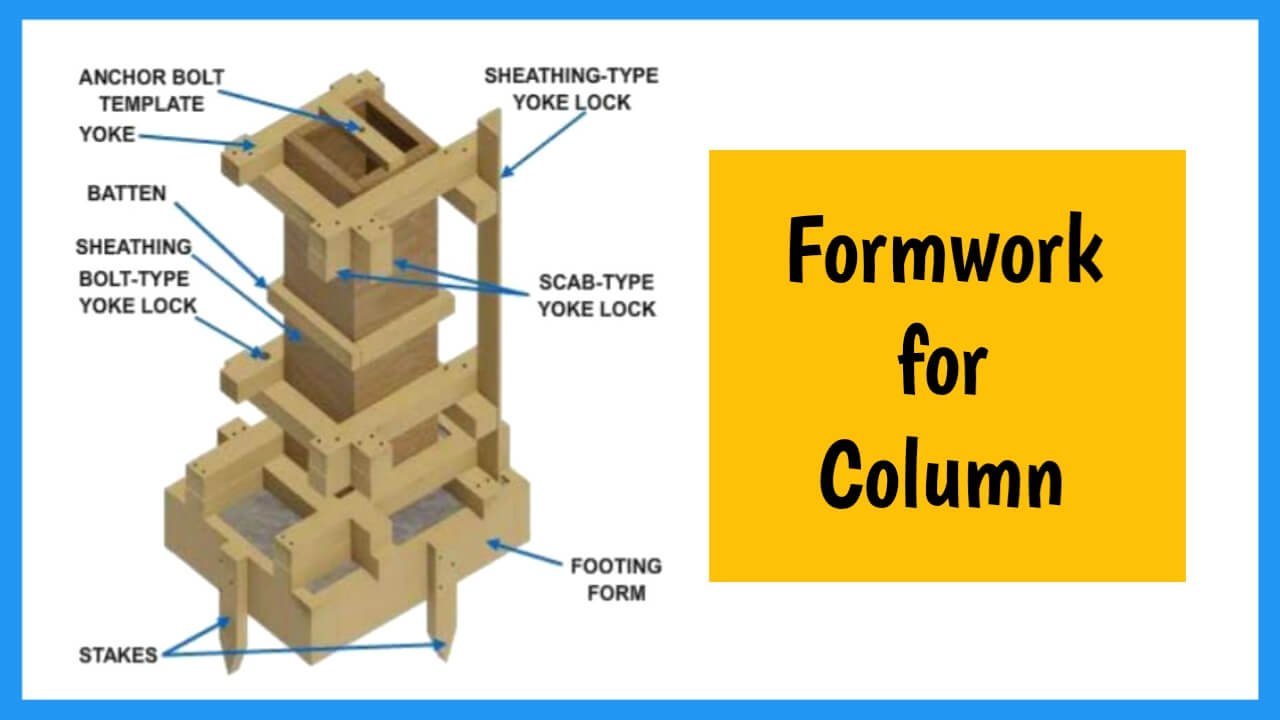

Formwork for Column:

Four planks is used in column formwork. Four plank are used to make box formwork for column.

Wooden blocks, bolts, yokes, etc. are used to hold the sides of the box in position.

The characteristics of the formwork for column are as follows.

- The formwork should be designed in such a way that it can withstand the high pressure generated if the concrete is filled quickly.

- Yoke spacing is kept at 1m.

- Depending on the shape of the column, the required boxes can be made.

- The formwork has a hole at the bottom called a cleanout hole or wash out hole. Before starting the concreting the formwork, the pieces of bricks, debris, etc. are removed through this hole and closed.

- Water is spray inside the formwork before starting the concreting work in formwork.

- The column box is designed so that the box can be used for another column with a few modifications.

- The nails should be kept slightly out without pressing, to make box easy to open.

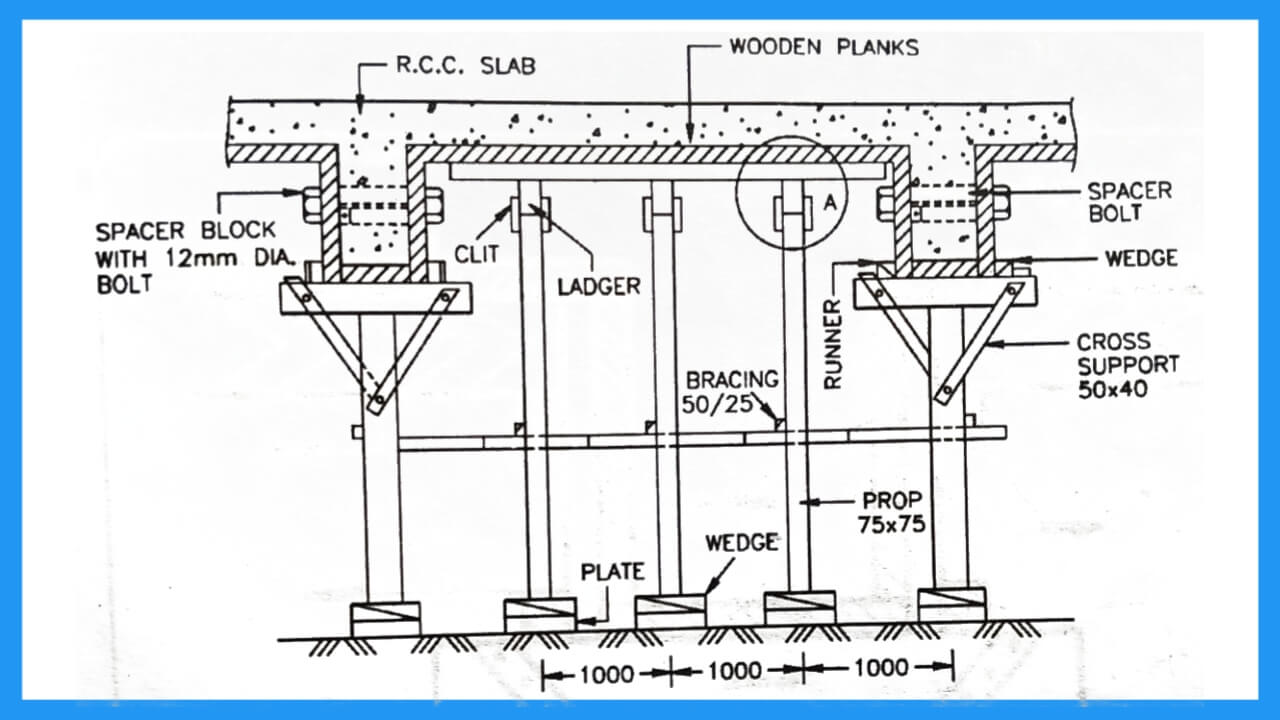

Formwork for slab:

Formwork for slabs consists of small beams at the head of vertical supports. These beams are supported by planks. A plank box is made for the end beam.

Vertical supports are strengthened by attaching horizontal supports. Also laterals, tapering blocks, base beams, wooden blocks, struts etc are used.

The following points should be kept in mind for the formwork of Slab.

- The formwork for the slab, should be designed keeping in mind the additional 30% weight of labor, materials, tools, etc.

- Posts are attached with diagonal braces if needed.

- Usually the steel formwork used for the slab and the rest of the parts of formwork are made of timber.

- Pillars should be supported exactly at the bottom end. Steel base plate, wooden wedge etc. is used for this purpose.

- The surface of formwork should be cleaned and sprinkled with water before pouring concrete over the formwork.

- The box of beams at the end of the slab is usually prepared at ground level and then placed in position.

Also Read: What is Slurry Wall Construction

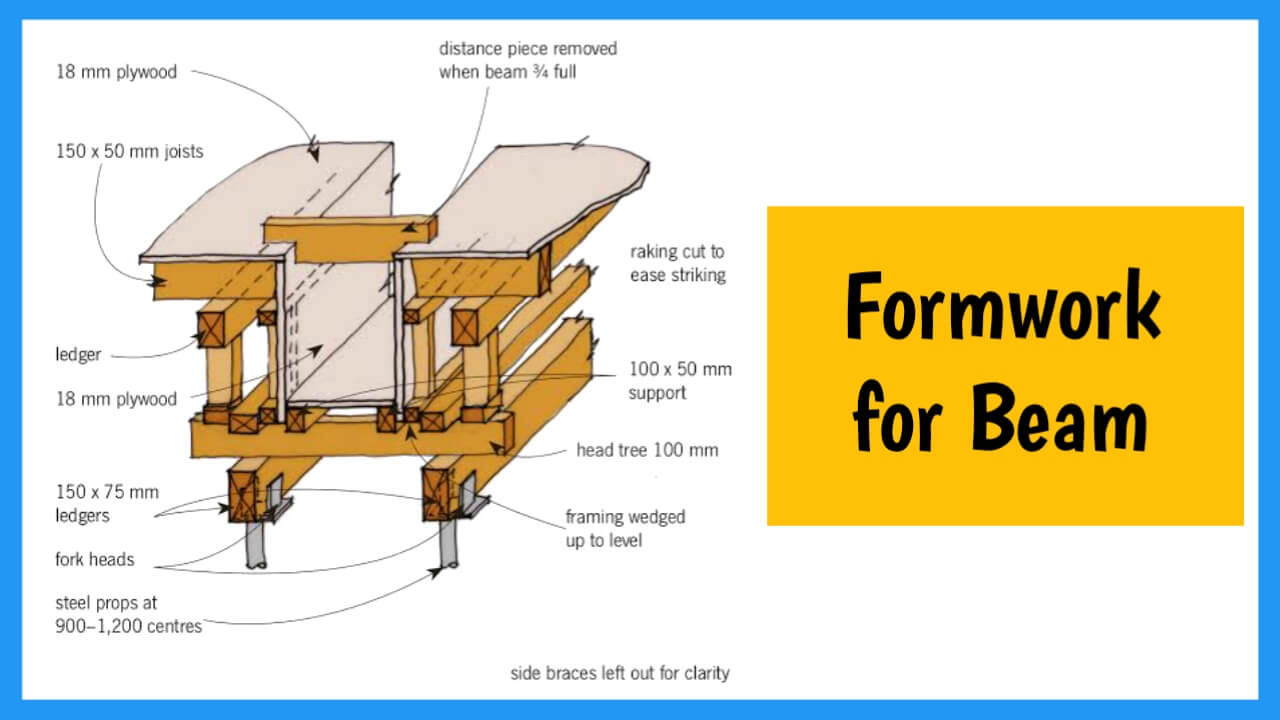

Formwork for beam:

Formwork for beam is shown in the figure. The formwork for beam is usually made with the formwork of the slab. The box for the formwork of the beam is made of two sides plank and the bottom plank. This box is supported on a pillar.

Frequently Asked Questions

What materials are used in formwork construction?

The materials used in formwork construction are listed below.

1. Timber

2. Aluminium

3. Steel

4. Plywood

5. Plastic, etc.

What is the distance between two yokes in column formwork?

The distance between two yokes in column formwork is 1 meter center to center.

What is most commonly used material for formwork?

The most commonly used materials for formwork are Timber, Aluminium and steel.

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.