Hello everyone, in this article i am going to explain what is slurry wall. Slurry wall construction procedure, advantages of slurry wall construction, limitation of slurry wall construction, ppt of slurry wall construction techniques, and etc.

So read the article till the end. Please help us to share this article with your friends when you like this article. Because sharing is caring

Table of Contents

What is slurry wall technique?

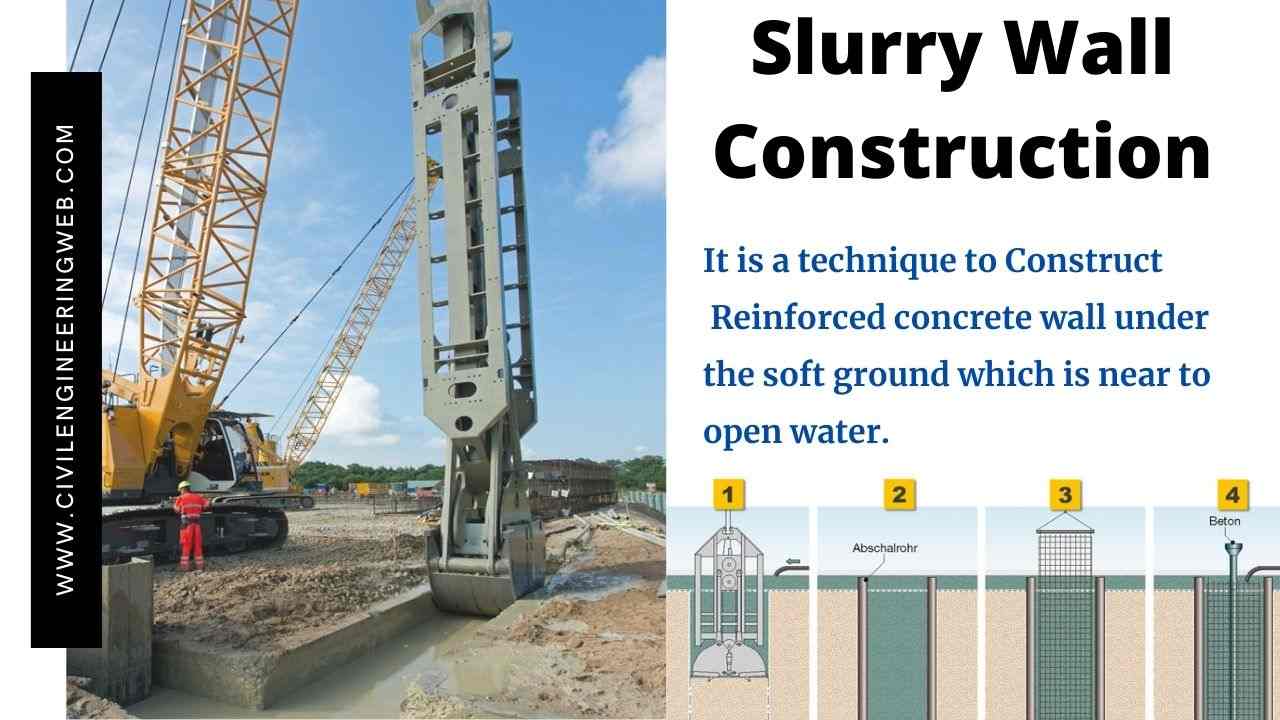

A slurry wall is a construction technique that is used to construct a reinforced cement concrete wall under the soft ground which is close to open water or with a high groundwater table.

Simply, it is a technique that is used to construct a diaphragm wall under the soft ground with any type of shoring.

The slurry wall is specially used to construct diaphragm wall, foundation, underground floors for the basement, etc. under the soft ground.

History of Slurry wall construction:

Slurry wall is first constructed in Line-1 of underground rapid transit system of Milan Italy.

It is used in the construction of a bathtub that is referred to as an underground foundation area of the world trade center, New York.

It is also used in foundation construction of taipai-101 building that is one of a tallest building in the world.

Also Read: What is Diaphragm Wall

Purposes of Slurry Wall construction:

Purposes of slurry wall construction are as follows.

- It is used for the seepage control in the underground construction.

- It is used for Cut-off curtains.

- It is used to prevent polluted ground water in construction site.

- It is used as Gas barriers for landfills.

Advantages of Slurry wall:

- It can be constructed at a very low cost.

- Using the slurry wall construction technique we can achieve High productivity of construction.

- Slurry walls have Very low permeability.

- Slurry walls provide excellent resistance against polluted groundwater.

- It can also resist horizontal forces like earthquake forces.

- In this technique, all the excavated material can be reused which means very little spoil of the material has occurred.

Slurry wall construction process:

The sequences of construction of slurry wall are as follow:

- Excavation

- Slurry Filling

- Placement of Steel Reinforcement

- Concreting

1. Excavation:

The first step of slurry wall construction is the excavation of trenches for reinforced concrete walls. The clamshell shaped digger or hydro mill trench cutter is used to make a trench and create a form for a reinforced concrete wall.

Also Read: How to construct diaphragm wall

2. Slurry filling:

The next stage of slurry wall construction is the filling with Slurry in the trench. A trench is filled with a slurry that is a mixture of bentonite and water. The trench is simentensoly filled with slurry while clamshell digging the trench.

Slurry prevents the collapsing of surrounding soil by creating outward pressure. That’s the reason, the slurry is used in the construction of the slurry walls.

3. Placement of Steel Reinforcement:

After the filling of the slurry in the trench, it is necessary to insert the steel reinforcement under the trench to make the reinforced concrete wall.

4. Concreting:

The final stage of slurry wall construction is concreting in the trench. The tremie pipe is used to fill concrete in the trench. Ready-mixed concrete is used in slurry wall construction.

Must ensure that the lower level of the tremie pipe is below the topmost layered of concrete that is prevent the mixture of slurry and concrete.

Slurry is come out due to the filling of concrete. Thus, this slurry can be used for the other slurry wall or it can be restored and used for other purposes.

So, this is the full construction procedure of slurry wall. Now the Limitations of slurry wall

Limitations of Slurry wall Construction:

- Required heavy machinery for construction of slurry walls like a clamshell digger or hydro mill trench cutter.

- Required skilled laborers.

- Required a high concentration on work and some precautions taken under consideration.

- Required a large area

Frequently Asked Question on Slurry Wall Construction

What is a slurry wall used for?

Slurry wall construction technique is used to create under ground reinforced cement concrete wall under soft soil.

How thick are slurry walls?

Generally, Thickness of slurry wall lies between 0.6 to 1m

What is Slurry Wall Construction Method || Process || Uses || Limitations || Techio Civil

What is Slurry Wall Construction Method || Process || Uses || Limitations || Techio Civil In this video, we explain what is slurry wall construction, the History of slurry wall construction, uses of slurry wall construction method, construction procedure of slurry wall, sequence, limitation and so more. so please watch the video till the end. Timestamp: 00:00 Intro 00:24 What is Slurry wall construction 00:43 History of slurry wall construction method 01:08 Uses of Slurry wall construction technique 01:21 Slurry wall construction procedure 02:59 Sequence of Slurry wall Construction 03:13 Limitation of slurry wall construction 03:29 Thank you Social network Instagram: https://www.instagram.com/techiocivil7 Learn More about civil engineering on my website. https://www.civilengineeringweb.com Learn Civil engineering in hindi at: https://www.hindicivil.in Please contact us for copyright matters at techiocivil7@gmail.com Please don’t forget to Like, Share, And Subscribe to our techio civil channel for more videos. #slurrywallconstruction #slurrywallconstructionvideo #slurrywallconstructionsequence #slurrywallconstructionprocess #slurrywallconstrutionmethod #slurrywallconstructiondefinition #slurrywallconstructionmeaning #usesofslurrywall #construction #advancedconstructiontechniques #civilengineering #constructiontechniques

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.