Ensuring workers’ safety is paramount in any construction project. There are several potential hazards in a construction site where protective equipment and proper safety protocols are the workers’ primary line of defense. Each equipment or gear helps mitigate exposure to certain risks and any damage that these hazards may cause.

All employees must be trained and aware of the construction safety protocols. Ergonomic accidents are entirely preventable with the implementation of construction safety measures. Using appropriately fitted PPE is equally essential since each piece should not cause discomfort or limited mobility.

Utilizing the appropriate safety gear will fluctuate depending on the construction site, the equipment, and the possible presence of chemical fumes. It’s essential to ensure safety on-site not only benefits the employees but your business as well.

Table of Contents

Construction Work Hazards and Risks

Building sites present numerous risks for workers, the first and foremost being the threat of falling. According to OSHA and the Census of Fatal Occupational Injuries prepared by the U.S. Bureau of Labor Statistics, these are the top causes of injuries onsite:

- Transportation incidents

- Exposure to harmful substances or environments

- Fatalities due to fires and explosions

- Unintentional overdoses due to nonmedical use of substances

In addition to the top causes of injuries and accidents listed above, it is also worth highlighting several potential risks in the industry which can lead to harm or damage:

- Lack of communication/ inadequate preparation

- Objects that are likely to strike victims, vehicles, or masonry walls

- Electrocution, due to contact with power lines or improper use of equipment,

- Being caught between objects due to unsafe access/egress, dangerous spoil-pile placement, or failure to inspect the trench

Also Read: What is Autoclaved Aerated Concrete [AAC]

Consequences of Construction Hazards

Understanding the risks and hazards in a construction site doesn’t always divulge the full story from an economic point of view. Companies that disregard the potentially damaging influence of on-site hazards pose a danger.

With an average cost of $27,000 per injury, there is undoubtedly a colossal consequence for unchecked risks in building projects. It is also worth knowing that the average fee across other industries for any harm is only $15,000 by comparison, making the construction industry a much more expensive sector when accidents occur. Moreover, contractors can incur significant fines if found to violate OSHA standards. Excluding the minimum violations where a verbal warning will suffice, penalties for severe violations start from $13,494, which can go up to 10 times.

Ultimately, the ramifications of hazards and risks should not be evaluated solely based on the loss to the business or site manager. For entry-level workers, beyond the apparent impact on their health and well-being, the effect of an accident can be immense and even lead to the livelihood of an entire family.

How to Prevent Accidents and Keep Workers Safe

In the United States, OSHA modulates the employer’s responsibilities for construction workers. Beyond the legal requirement, there should also be a moral duty of care towards employees, which extends to their mental and physical well-being, benefiting both the business and workers equally.

Follow all OSHA guidelines.

From a ruling perspective, OSHA imposes regulations to provide a secure work environment while including the following:

- Ensure that construction sites are free of recognized hazards as much as possible.

- Comply with all standards, rules, and regulations issued under the OSH Act.

- Examine working conditions to ensure they comply with OSHA standards.

- Provide safe tools and equipment that have the best possible standard.

- Place accurate warnings to highlight potential hazards to workers, including color codes, posters, or labels).

- Have in place clear operating procedures which are updated as required and communicated clearly to employees.

- Ensure that every onsite work has adequate training beforehand. Training is provided in a language and vocabulary that workers understand, especially given the high percentage of immigrant workers in the construction industry.

- Implement a communication program if employees work with hazardous chemicals.

- Provide medical exams and training.

In addition to clear and comprehensive safety practices, workers in the construction industry must be transparent and honest about hazards and incident reports.

Also Read: What is Monolithic Construction Technology

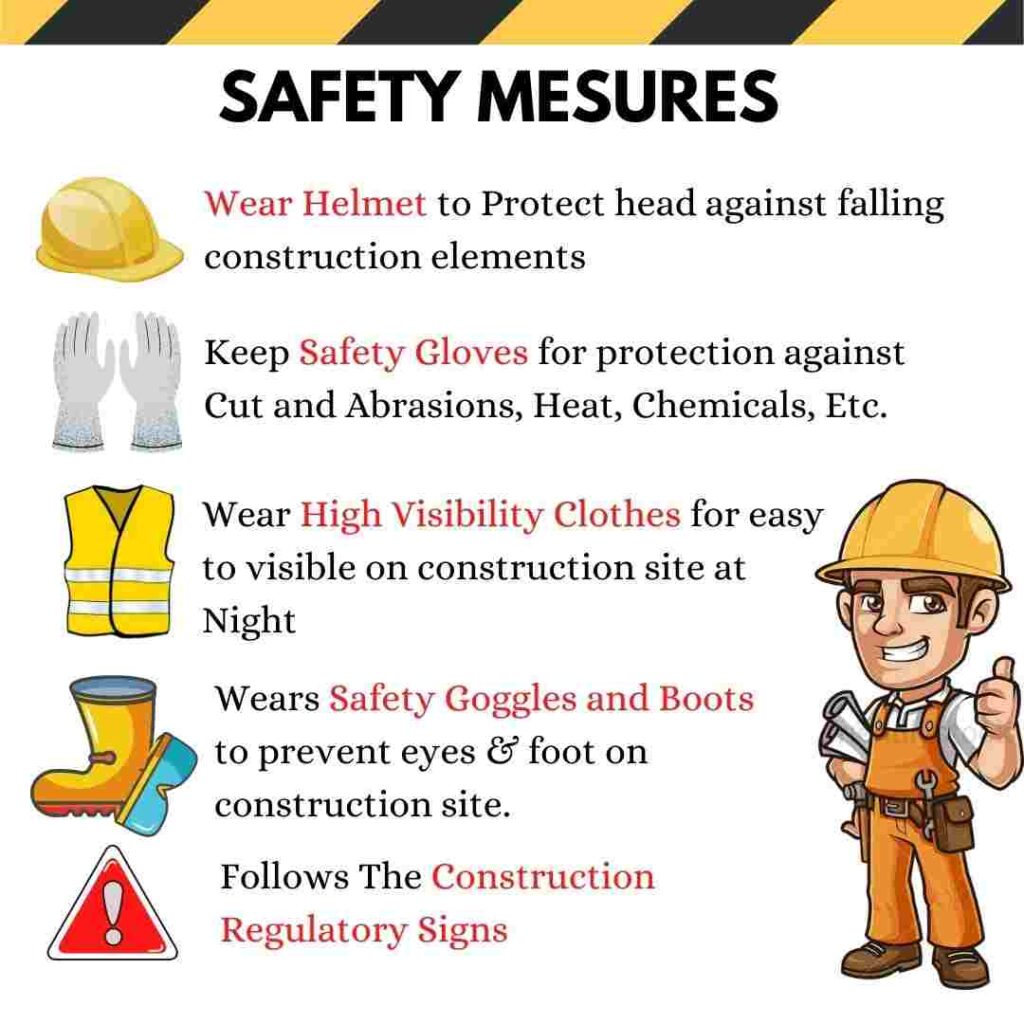

Necessary Safety Gears and Measures to Implement

There are several instances in which an employee can be injured during a construction project. Wearing the appropriate gear and equipment can substantially minimize any risks or chances of accidents occurring and reduce the severity of potential injuries.

Here are some general tips for workers and employers to keep in mind and some regulations to follow to ensure a safe work environment on construction sites.

1. Fall Protection

Falling incidents are the most cited standard in construction projects and are one of the leading causes of fatality in the workplace. Project managers must assess job sites and implement fall protection protocols to control everyone on-site.

Workers: Familiarize workers with all potential hazards and areas susceptible to falling accidents on the construction site. Employees using personal fall arrest systems should thoroughly inspect each harness to ensure that it is working correctly.

Employers: Employers should provide fall protection systems to safeguard workers from walking or working surfaces with unprotected edges six feet above the lower level. These areas are guardrails, safety net systems, and personal fall arrest systems. When conducting work on roofing systems, make sure to install a reliable roof hatch safety railing to keep workers safe.

Protecting workers from other vulnerable areas such as elevator shafts, skylights, and excavations constitute the fall protection system. Employers must also require workers to wear hard hats at all times.

2. Scaffolds

The majority of construction workers perform their duties on scaffolds. Employees are at risk of falling accidents, electrocutions, and falling object hazards.

Workers: Workers should wear hard hats when working on, under, or around a scaffold. Employees must wear proper gear such as non-skid worker boots and tool lanyards to prevent slips and falls and protect workers underneath. Avoid working on scaffolds covered with ice, mud, and water. Workers are not allowed to use tools that increase their height when on the scaffold. Employees must strictly follow the scaffold’s maximum weight requirement and never leave any equipment or materials at the end of the shift.

Employers: A professional must install all scaffolding in an area with solid footing, fully planked, and at least 10 feet away from the power lines. The same person who assembled the scaffolding also needs to inspect its durability to ensure safety for all workers.

Also Read: Precast Concrete Vs Site cast Concrete

3. Eye and Face Protection

OSHA requires workers to gear themselves up with proper eye and face protection equipment when assigned to work with flying particles, molten metal, liquid chemicals, acids or caustic liquids, chemical gasses or vapors, or potentially injurious light radiation. These potentially dangerous hazards are present when doing a wide array of tasks on the construction site, including welding, chipping, grinding, masonry work, sanding, woodworking, and drilling.

Workers: Workers must ensure that both equipment snuggly fits and does not interfere with their movements. They also need to inspect the face and eye protection gears for cracks, chips, and other damage.

Employers: Employers must provide all workers with eye and face protection equipment that meets one of the following standards: ANSI Z87.1-1989 (R01998), ANSI Z87.1-2003, or ANSI/ISEA Z87.1-2010 regulations. Project managers must also require employees to wear critical eye and face protection equipment to assess potential safety hazards.

4. Head Protection

Hard hats are the most common and reliable safety equipment on construction sites. They protect workers and employers from several safety hazards such as falling objects, electrical shocks, and other impacts.

Workers: Workers are required to wear hard hats at all times whenever inside the site or doing tasks that increase the chances of being struck in the head, such as falling tools or debris, accidental nail gun discharge, contact with electrical hazards, or swinging construction equipment. Hard hats must fit snugly on your head and must not have any cracks or signs of deterioration.

Employers: Project managers provide all workers with head protection that adheres to the consensus standards outlined by the American National Standards Institute (ANSI). Hard hats must be provided free of charge and kept in good working condition, and replaced immediately at the first sign of damage or deterioration.

Also Read: What is Slurry Wall Construction

5. Excavation Hazards

Excavation and trenching work are some of the more hazardous tasks on construction sites due to a substantial amount of potential danger or safety hazards that may be present. These risks include cave-ins and electrocutions from hitting utility lines, slips and falling loads, and heavy machinery incidents.

Workers: Workers must always wear hard hats when excavating work to protect from falling objects or being struck by equipment. Never enter a trench site without a thorough inspection, and proper safety systems are in place. They should also never stand underneath heavy loads handled by heavy machinery and steer clear away from the edge of excavations to prevent falls or cave-ins.

Employers: Employers are required to have all utility lines identified and marked before allowing employees to work on excavation sites. For digging sites over five feet, a professional engineer must design a protective system by sloping, shielding, or supporting the excavation unless it’s in solid rock.

Project managers are also responsible for hiring a professional to properly inspect the excavation site for potential cave-ins, possible failure of protective systems, and atmospheric hazards. They should also provide workers with proper and safe ingress and egress points on the whole trench site.

Protective gears and safety protocols in construction sites are mandatory at all times. Providing all workers with the right equipment and proper safety training can boost morale for all involved, leading to efficient productivity. With fewer injuries and accidents to cover, your business stands to gain more productive working hours, resulting in better profitability.

Also Read: 14 Different Special Types of Concrete

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.