In this article we explain how to do strengthening of existing slabs. various methods of strengthening of slabs. slab jacking technique, strengthening of interior reinforcing. advantages and disadvantages of slab jacking techniques, how to do slab strengthening by using shotcrete methods and so more. please read the full article till the end.

Table of Contents

Strengthening of slabs:

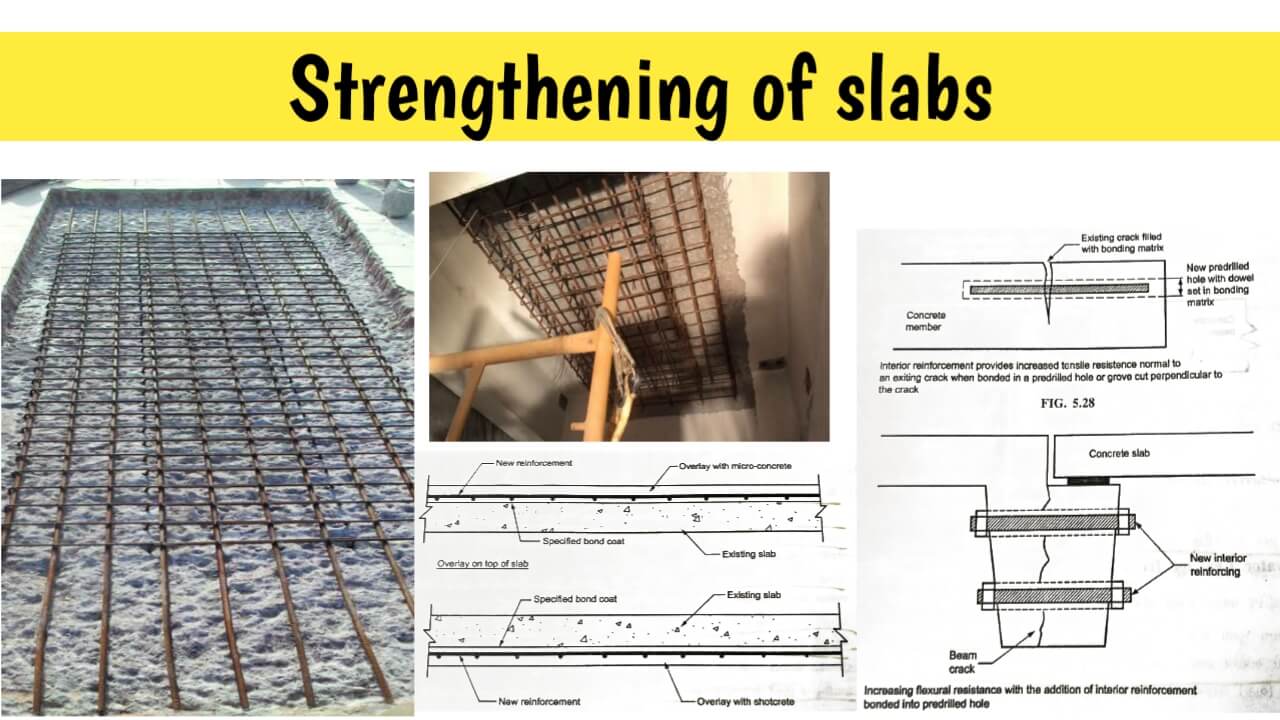

The “Over lay” or “Under lay” is done to increase the Flexural (banding) performance of the slab. Such “over lay” or “under lay” increases the stiffness of the slab and reduces deflection.

When the negative Bending Moment (hogging) is more than do ‘overlay’ and positive B.M. (sagging) If there is more than do “underlay”. The slab is usually safe in the shear, so there is no need for reinforcement for the shear except for the flat slab.

Strengthening of slabs is depend on the slab condition and which defects is occur in slab. It is necessary to increase the durability of structure.

When carbonation defects occur in slabs and depth has reached to the reinforcement level of the slab than Strengthening of slabs is very important.

In which Slabs the carbonation depth has reached the reinforcement level of the slab, that type of slabs repaired as follows.

1. Repair with Polymer Modified Cement Mortar:

This method is used for small patch repair. The steps of this repair method are as follows:

- First To support the damaged slab.

- Remove any loose concrete from damaged slab

- Cleaning the Reinforcement corrosion. Placing additional reinforcement steel where required. Remove the concrete up to 15 mm around the reinforcement.

- Apply corrosion resistant coating (cement slurry or epoxy coating) on the surface of reinforcement rod. Apply bond coat on concrete surface.

- Then do Repair work by applying polymer modified cement sand mortar layers on the prepared surface. The surface of the reinforcement rod should have a mortar cover of at least 15 mm. The thickness of the mortar layer should not exceed 10 mm and the total thickness of the mortar should not exceed 30 mm.

- Then do Curing the surface with water for 7 days.

- Then paint the surface with whitewash or cement paint.

2. Shotcreting:

The Shotcreting method is used when repairing slabs, over a large area.

- First To support the damaged slab.

- Remove any loose concrete from damaged slab

- Cleaning the Reinforcement corrosion. Placing additional reinforcement steel where required. Remove the concrete up to 15 mm around the reinforcement.

- Apply corrosion-resistant coating (cement slurry or epoxy coating) on the surface of reinforcement rod. Apply a bond coat on the concrete surface.

- Then do Shotcrete to an average thickness of 50 mm on the prepared surface.

- Apply finishing plaster on the shotcrete surface after 48 hours.

- Then do Curing the surface with water for 7 days.

Slab Jacking Technique:

The technique of lifting a slab sitting on the soil by pressure ejection grout is called Slab Jacking Technique‘.

This is called slab jacking when the slab is to be lifted by pressure injection. But when only the holes are to be filled, it is called ‘pressure grouting’.

Applications of Slab Jacking Technique:

- Highway maintenance

- Repair of expansion joints

- Repair of Settlement damage in RC slabs

Advantages of Slab Jacking Technique:

- Slab Jacking Technique is cheaper compare to other repair methods

- Slab Jacking Technique takes less time compare to other repair methods.

- Grout pumps and other large equipment can actually be kept away from the repair area.

- The grouting schedule can be adjusted without affecting other activities.

Strengthening of Interior Reinforcing:

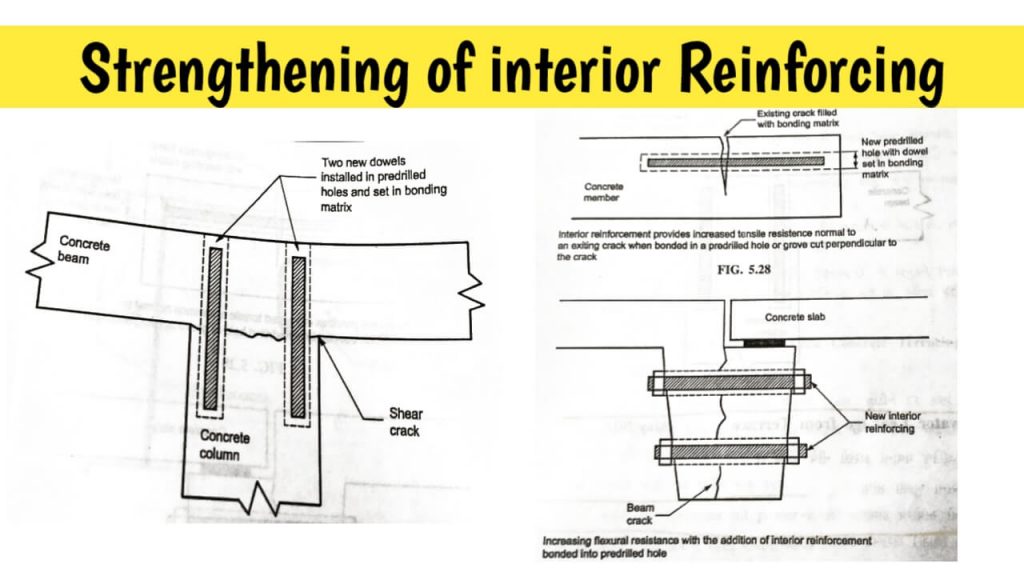

Strengthening of Interior Reinforcing A well-known method of drilling holes and inserting new dowel bars to insert excess steel into cracked concrete. Such dowel bar are placed at right angles in cracks. A bonding matrix is used to attach the dowel bar to the concrete.

Dead load stresses should be reduced by supporting the member before placing a new dowel bar. Bonding materials such as Portland cement grout, epoxy, etc. are filled in the space around the drilled hole by inserting a dowel bar.

Such dowels are made of deformed steel bars, stainless steel rods or bolts. Steel dowel bars should be coated with zinc galvanizing or epoxy.

When there is a horizontal crack near the junction of the beam and the column, a hole is drilled in the slab at the top to transfer the shear and a dowel bar is arranged at the top to fill the bonding material.

Bonding of dowel bars is done in one section of concrete. While in the second section the de-bonding agent is filled.

Advantages :

- This way reinforced concrete damaged by flexural or shear stress can be strengthened.

- The method is simple, tools are simple to use.

Limitations:

Inside reinforcement bars cannot be cut.

- drilling is difficult. External strengthening method has to be used.

- Internal Dowels cannot be placed in the damaged concrete.

Also read:

- 5 Method To Repair Brick Wall Defects || Repair of Brick Wall Cracks etc.

- 8 Aspects to Make Earthquake Proof Masonry Construction

- How to Repair of Stone Masonry Defects | Strengthening of Stone Masonry

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.