we explain what is pile foundation?, when and where pile foundation is used, types of pile foundation based on function, use or material. types of concrete pile, steel pile. advantages and disadvantages of various types of piles and function, objective of sheet piles etc.

Table of Contents

What is Pile foundation?

Pile foundation is one type of deep foundation which is used when the bearing capacity of soil is low, in under water construction, load of structure is high, location where shallow foundation is not possible, etc.

When Pile Foundation is Used?

- Load coming from the structure (load) is too high and its distribution over the soil is not uniform.

- The bearing capacity of the soil is low and the required holding capacity is obtained at a greater depth.

- Fluctuates Sub-soil water level.

- Construction of a raft or grillage foundation may be too expensive or not feasible.

- The timbering of the excavation is very difficult.

- Dewatering water from a base trench is very expensive.

- In the area, where future pipelines for water, sewerage, gas etc. are to be laid.

- If the structure is located on the beach or on the bank of a river and there is a possibility of erosion of the foundation due to waterlogging.

- Pile foundation is useful for the foundation of the structure in the sea.

- Anchor piles are used to provide grip against upward pressure and lateral pressure on the structure.

- In marine constructions like dock, pier, fender piles are used to protect the construction from the impact of ships.

Types of pile foundation based on function or use:

- End bearing pile

- Friction pile

- Compaction pile

- Tension pile

- Anchor pile

- Fender pile

- Better pile

- Sheet pile

1. End bearing pile:

This type of pile is used to transfer load from water or soft soil to the hard rock below. The load is transferred to the lower end of the pile.

Qu = Qp is used for this pile.

2. Friction pile:

The surface of such pile is kept rough so that the load is carried by the friction (skin friction) generated between the surrounding soil and the surface of the pile.

For a friction pile, Q = Qs

Qu = Ultimate load on pile Qs = Skin friction

The carrying capacity of the friction pile can be increased as follows:

- By increasing the diameter of the pile

- By insert pile to a greater depth.

- By make roughing surface of the pile.

- By keeping group of pile.

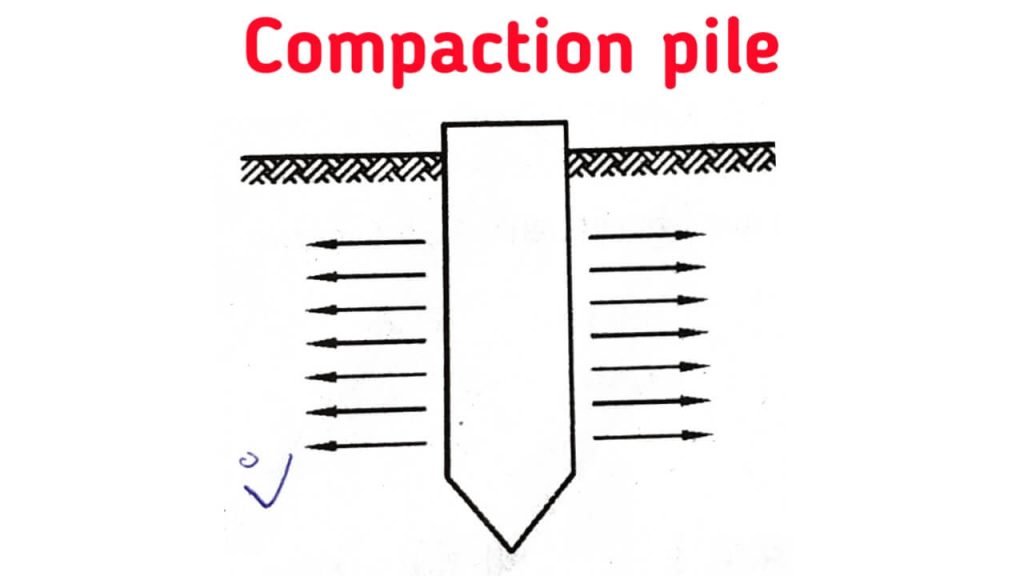

3. Compaction pile:

When a pile is insert into granular soil to increase the bearing capacity of the soil, it is called a compaction pile.

Pile itself does not carry any load, so it is made of weak material. Sand piles are commonly used as compaction piles. In which a pipe is insert into the ground, so that the soil around the pipe undergoes lateral movement and compaction of the soil occur, then the pipe is slowly pulled out and filled with sand. This is how the sand pile is prepared.

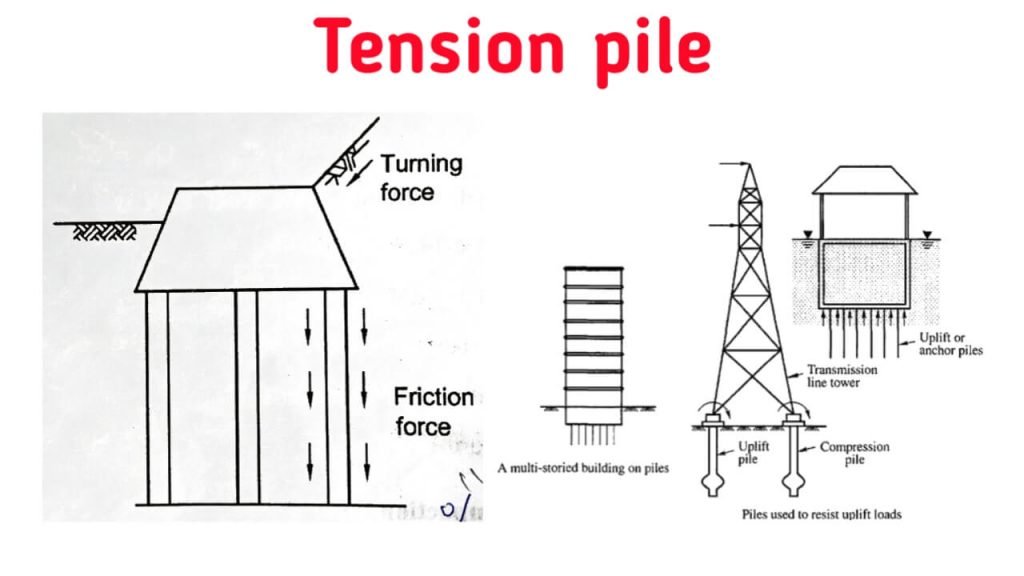

4. Tension pile:

When a structure feels uplifted due to ground water pressure or due to overturning moment, tension pile is used to keep the structure attached to the ground. In such a pile tensile strength is generated.

The resistance to tensile force is due to the force of friction with the soil on the surface of the pile.

5. Anchor pile:

When a pile is used to provide anchorage against the shear pull of a sheet pile or other type of pulling force, it is called an anchor pile.

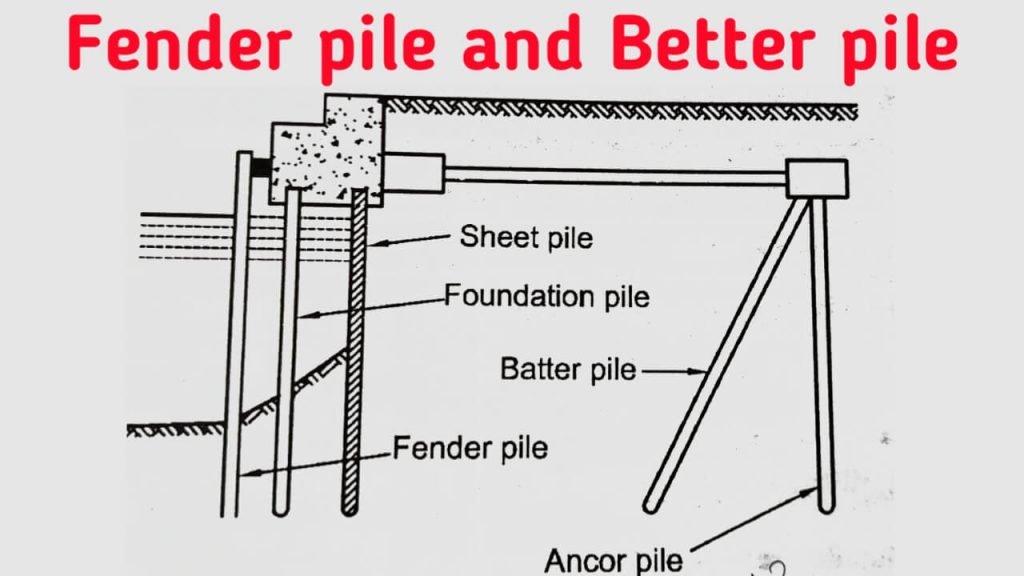

6. Fender pile:

A pile that is used to protect a structure in the sea from damage caused by abrasion or collision of a ship is called a fender pile. Such piles are usually made of wood.

7. Better pile:

When the pile is insert into the ground to prevent horizontal force or transverse force, is called Better pile.

8. Sheet pile:

The main function of sheet pile is to separate two members under the ground. Such piles are not designed to withstand any vertical loads.

The sheet pile is used for the following purposes.

- To separate the base from the lateral soil.

- To stop the movement of ground water, which is very necessary for cofferdam.

- To prevent the vibrations of the machine from reaching the side structure.

- To build maintenance wall for marine works like docks, wharfs.

- To prevent erosion of river banks.

- To support the sides of the base trench.

- To build cut off wall below the dam.

- To increase the holding capacity of soil by keeping it confined.

- To prevent erosion of the foundation of the river by river or sea water.

Types of piles based on materials:

Different types of piles based on materials are as follows:

- Concrete piles

- Steel piles

- Timber piles

- Sand piles

- Composite piles

1. Concrete Piles:

Concrete Piles is made of R.C.C. Its compression strength is very high. Types of concrete piles given below.

2. Steel piles:

- H – beam pile

- Box pile

- Tube pile

i. H – beam pile:

Rolled steel H – beam is most commonly used as steel pile. Often, such paddles are used as columns to keep them open to a certain height outside the ground.

H-beam piles have a very small cross section and can be easily inserted into the ground where normal piles are very difficult to insert into the ground.

Such piles are more suitable for digging deeper in loose soil as well as where normal piles are likely to damage the surrounding piles.

After such a pile is inserted to the required depth, its head is cut into squares and covered with a thick steel plate or concrete cap.

Such piles are used in the construction of retaining wall, bridges, trestles, cofferdams etc.

ii. Box pile:

Different patented box piles are available. The pile is the Larsen box pile. Which are rectangular or octagonal in shape. Such piles are made by assembling different steel sections.

The pile is inserted into the ground like any other pile. The bottom of pile can be closed or open. The box is then filled with concrete. When the box pile is inserted into the ground, it moves a large amount of soil so that the end resistance and friction resistance are greatly increased.

This type of pile can be used successfully where it is not possible to insert the H-beam pile to a hard level.

ALSO READ: Types of shallow foundation || when and where use

iii. Tube pile:

In this type of pile, steel tube or pipe is inserted into the ground. These piles are also grounded with open ends or closed ends. Pipes range in diameter from 25 cm to 120 cm. Pipe wall thickness ranges from 8 cm to 12 cm.

Open ended pile are normally use for hard layer soil. The inside soil of the pile is removed with water jet or compressed air. After inserted pile into desire level, concrete fill inside the tube pile.

Close-end pile is usually used for loose soil. After the pile descended up to the desired depth, it is filled with a concrete. It is easy to insert in soil and replace due to its circular cross section.

Advantages and Disadvantages of Steel Piles:

Advantages:

- Easy to Resistant against forces which is developed due to inserting pile in soil.

- Increases in the length of the pile can be done easily by welding.

- Additional lengths can be easily cut.

- Bearing capacities of such piles are much more.

- The pile can be easily replaced without damaging.

- Such a pile has great resistance against impact shock, due for this reason it is more useful for marine construction.

- Such a pile does not damage from sea insects.

- Box piles are saved the cost of filling mortar or sand between piles.

Disadvantages:

- Steel pile easily damage due to corrosion.

- The pile can be protected by making a coat of paint on it, but it increases costs.

3. Timber Piles:

Timber pile is circular or square-shaped. The diameter of the circular pile is 30 cm to 50 cm. The size of the square pile is as much as 50 cm to 30 cm. The length of the pile should not be more than 20 times the width of its top, so that it does not bend.

The steel shoe is attached at top of pile and cast iron shoe is attached in bottom of pile.If Timber used in a pile group, a concrete cap is placed above all the pails. The best margin between two pile is 90 cm central gaps. The load on Timber pile should not be more than 20 tons.

Advantages and disadvantages of the timber pile:

Advantages :

- Such piles economical where the wood is easily available.

- Due to less weight, it can be easily transported without being damaged.

- An increase in the length of the pile or reduction can be easily done with a low cost.

- It does m not require heavy machinery and skilled supervisors.

- The pile can be easily inserted in the soil.

- The pile can be easily pulled out if needed.

Disadvantages:

- Erosion of pile due to clay, seawater, or insects.

- Can’t take more load such pile and cannot be used as an end-bearing pile.

- Inserting of timber pile in hard soil strata is impossible.

- It is difficult to get the required length and size of the piles.

- If the pile is not treated then, its durability is very low and its lifespan is less.

4. Composite Pile:

In this type of piles, Two different materials are placed in the ground on each other and both piles work together. ex – combination of wood and concrete

This combination of wood and concrete is taken advantage of the durability of concrete and cheaper wood.

The lower part of such pillar is made up of wood.

Advantages and disadvantages of Composite pile:

Advantages:

- It is cheaper.

- It can be easily created.

- Where other types of piles are not convenient, the combination piles can be used corresponding to the type of land.

Disadvantages:

- Strength of pile weak if the pile does not have a proper connection between two different materials in the formation of the pile.

v. Sand Piles:

in this type of pile, making hole in ground and it is filled with sand. If the sand is surrounded, then its loading capacity are too high and it becomes a incompressible.

The diameter of sand pile is usually as 30 cm. Drilling hole by the help of Timber pile or augur or closed pile in the ground. The wet sand is filled in this hall and the sand is properly compacted. The heading part of pile is filled with a concrete, so that the sand does not exit from sand pile.

The sand pile is usually made below the structure column from 2m to 3m center to center. The length of this pile should not more than its 12 times diameter. Sand pile can bear the load as much as 100 Ton/m2.

Advantages and disadvantages of sand pile:

Advantages :

- Such piles are economically for small houses and road embankments.

- Easy to construct.

- Gravel can be used instead of sand.

- There is no effect of the ground water or underground burning.

Disadvantages:

- Such piles are not favourable for soft soil.

- Where is a possibility of erosion there it is not convenient.

- Not suitable for earthquake region.

ALSO READ : What is ferrocement? Application, method of construction Uses.

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.