Cement is an important element of concrete that affect the durability and quality of concrete. That is why it is necessary to check the quality of cement by performing field and lab tests on cement.

The test of cement defines various properties of cement and give an idea about cement is best or bad for our construction project.

Major Two types of test performing on cement.

- Field test

- Laboratory test.

Table of Contents

Field test on cement:-

Field test of cement is performing by given ways, which are given below.

- First, open the bag and see the cement there not have any lumps in cement, and the color of the cement is similar to greenish-grey.

- Then Put your hand inside the cement bag. And feel cement temperature. The good cement gives a cool feeling.

- Take in a pinch of cement in your finger and feet it. The cement gives a smooth feeling. Poor quality cement gives gritty feelings not give a smooth feeling.

- Take one fist of cement and throw it on a water full bucket. The particle of cement floats on the water before sinking inside the bucket.

- Take a small quantity of water and 100 grams of cement and make a stiff paste of cement and water. Then make a cake of stiff paste with sharp edges. Put cake of stiff paste above glass plate. Then take it and keep it underwater inside the bucket. See the shape of the cake is not disturbed during placing inside water. And also see After 24-hour stiff paste cake retains its original shape and gains some strength.

Laboratory test on cement:-

The laboratory test on cement are given below.

- Fineness test.

- Standard Consistency Test

- Setting time test.

- Compressive Strength Test.

- Soundness test.

1. Fineness test on cement:-

Here we explain how to do a fineness test on cement in a laboratory. And some important parameters of the fineness test of cement.

The fineness test of cement is important for various parameters like the hydration process and heat of hydration is totally dependent on the fineness of cement. Finer cement produces high heat of hydration and gives strength rapidly.

The fineness test of cement is performing in two ways.

- Sieve test.

- Air permeability method.

a.) Sieve test:-

In this test first, take correctly 100gram cement and then put on standard sieve IS 90 micron. Break the small air lumps with fingers. Then continuously sieve the sample by giving horizontal and vertical motion for a period of 15 minutes.

You can also use a mechanical device to perform sieving. Then weigh the residue left on the Indian standard sieve. This residue weight shall not exceed 10% of the ordinary cement weight.

b.) Air permeability method:-

Air permeability method is mostly used to check the fineness of cement. In this test specific surface area ( total surface area of all particles in one gram cement) of cement, particle is determined by the air permeability apparatus.

Generally, for the air permeability test Blaine air permeability apparatus is used. But also another apparatus is used for air permeability tests like Lea and Nurse air permeability apparatus.

The principle of this test relies on the relation between the flow of air through the cement bed and also the surface area of the particles comprising the cement bed. From this the area per unit weight of the body material can be related to the permeability of a bed of a given porosity.

The full description of this test is given in book of concrete technology by ms shetty.

2. Standard Consistency test on cement:-

The aim of performing standard consistency test on cement to find out the percentage of water required to make cement paste with Indian standard consistency.

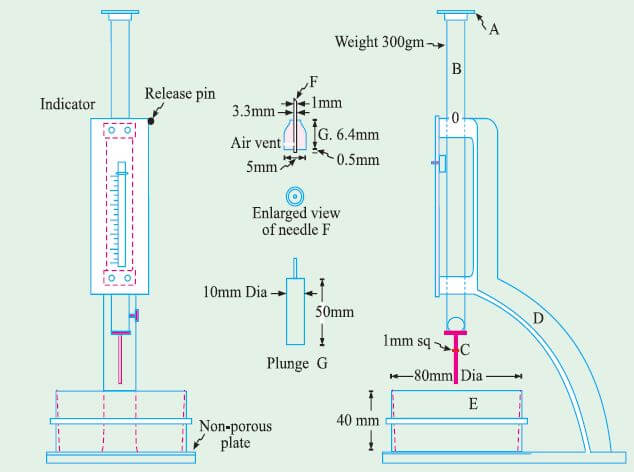

- In this test Vicat apparatus, Vicat mould, and a standard plunger are used.

- The procedure of this test is given below.

- First Take 500gms of cement and prepare a paste with a weighed quantity of water (say 24 percent by weight of cement) for the first trial.

- The paste is prepared in a standard manner and fill this paste in the Vicat apparatus mould.

- After preparing the paste fill the paste within 3 to 4 minutes.

- After completely filling the Vicat mould, apply vibration or compaction on it to remove extra air and void from mould paste.

- After completing compaction takes Vicat plunger (10mm dia and 50mm long) and attached to Vicat apparatus then move down and keep on paste surface (touch to paste surface).

- Then quickly released plunger and allow to it sink in mould paste by its own weight.

- Then take the reading. If the depth of penetration of the plunger is not 33 to 35mm then try 2nd trial.

- In the 2nd trial take water 25% of cement weight and make the paste in a standard manner.

- Then repeat the above procedure and take the reading of penetration. If the depth of penetration is not satisfied above criteria then make 3rd trial and try it.

- In every trial add extra 1% water of cement weight and try until you not get the above result.

- That particular percentage of water that allows the plunger to penetrate a depth of 33 to 35mm from the top is known as the percentage of water that is required to make standard consistency of cement.

Click here to see Best books for concrete technology on amazon

3. Setting time test on cement:

- Initial setting time on cement

- Final setting time test on cement

a.) Initial setting time test on cement

Initial setting time of cement is defined as the time at which cement paste is starting to gain hardening strength (reducing its plasticity) after adding water.

The following procedure are taken out to check initial setting time of cement.

- This taste is also similar to a consistency test.

- In this take first take 500gms cement and add water (0.85 times of water to make cement paste of standard consistency (0.85p)) and make cement paste in a standard manner.

- Start the stopwatch when water is added to the cement. And also note the temperature.

- In this test, a 1mm diameter needle (c) is used for penetration purposes.

- Lower the needle bring it in contact with the surface of the mould paste and quickly release.

- Allow it to penetrate in mould paste. Beginning the needle is completely penetrate. But after some time when the paste starts losing plasticity, the needle may penetrate only to a depth of 33 to 35mm from the top.

- The time between water add in cement and the needle penetrate only to a depth of 33 to 35mm from the top is known as initial setting time of cement.

b.) Final setting time test for cement:

This test is also similar to Initial setting time test.

In this test the needle (c) is replaced with circular attachment needle of the vicat apparatus.

The cement shall be considered as finally set when, upon, lowering the attachment gently cover the surface of the test block, the center needle makes an impression, while the circular cutting edge of the attachment fails to do so.

In other words, the paste has attained such hardness that the center needle does not pierce through the paste more than 0.5 mm.

4. Compressive strength test on cement:

The aim of this is to check compressive strength of cement.

The following procedure is adopted to check compressive strength of cement.

- In this test first, take 555-gram standard sand, 185 mm gram cement (maintain 1:3 cement/sand ratio).

- Prepare a dry mix of cement sand on enamel tray. Properly mix for nearly one minute.

- Then add water of quantity p/4 +3 percent of the combined weight of cement and sand. Where p = water required to make cement paste of standard consistency.

- Then mix properly. The time of mixing should not be less than 3minutes or not more than 4minutes.

- Then the mixed mortar fills in a cube mould of size 7.06m.

- Compact the mixed mortar properly by hand or mechanically.

- Then keep the cube at room temperature.

- Then remove the cube from mould after 24hour and immersed it in clean fresh water.

- Then also make 2cubes as above procedure and keep for curing.

- Then the compression test carried on the first cube after 3 days.

- Second cube after 7day.

- And the third cube after 28 days.

- Compressive strength is an average of all three cubes.

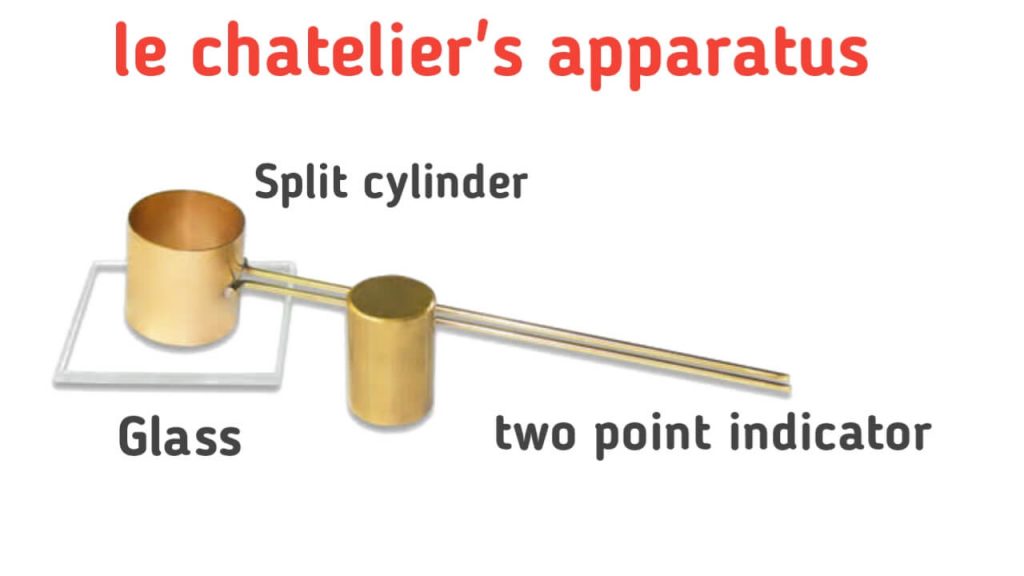

5. Soundness test of cement:

The aim of this test to check change of volume of cement after setting.

The change of volume of cement is serious difficulties for durability of structure when such cement is used.

The excess of lime, inadequate burning of cement, not proper grinding, high proportion of magnesium content or calcium sulphate content causes unsoundness properties of cement.

the following procedure taken in this test

- The apparatus used in this test consists small split cylinder of brass. The size of this apparatus is 30mm in diameter and 30mm long.

- Two indicator arms 160 mm long attached on both sides of spilt cylinder.

- In this test cement is mix with water (quantity of water = 0.78 times of the water required for standard consistency) in a standard manner.

- Then fill this cement paste in mould.

- Put mould on a glass plate.

- Then cover mould with a glass plate.

- Then the whole assembly is immersed in water at room temperature for 24 hours.

- After 24 hours measure the distance between the two indicator points.

- Then again submerged mould in water and heat the water and bring to boiling point in half hours.

- Then do boiling of mould for 3hours.

- Then remove the mould from hot water and kept mould at room temperature and allow to cool it.

- After cooling of mould measure the distance between the two indicator points.

- The difference between these two measurements does not exceed 10mm.

- This measurement represents the expansion of cement.

Test On Cement Pdf Download

ALSO READ:

What is Ferrocement? material, construction method, application, advantages.

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.