Table of Contents

Cryogenic Tanks – What is it?

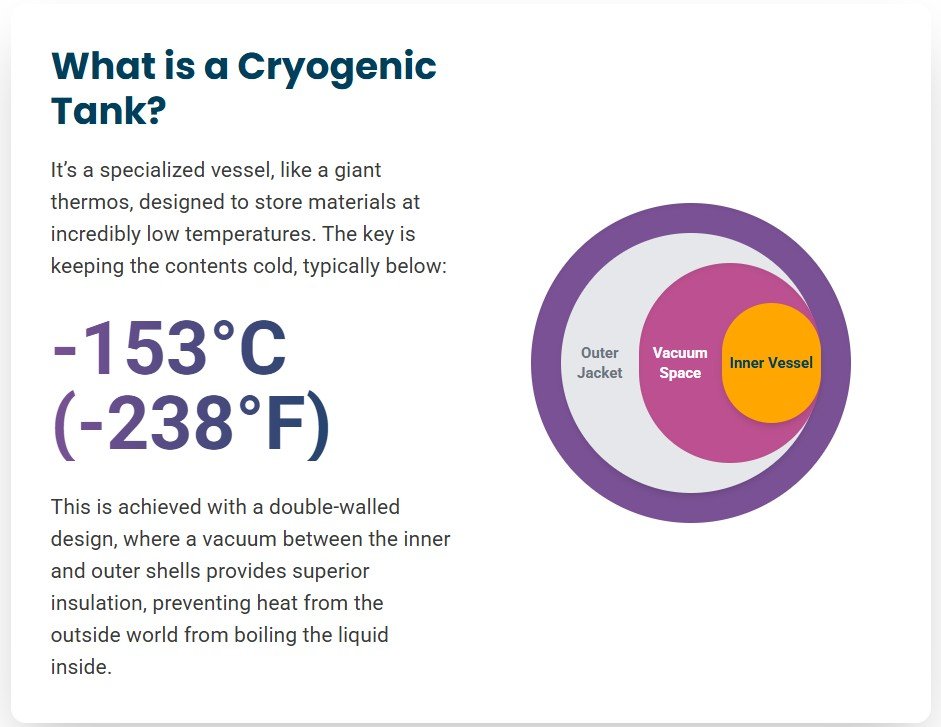

Cryogenic tanks are specialized storage vessels used to store gases in liquid form at extremely low temperatures, usually below -153°C. These tanks are vital for various industries including energy, healthcare, manufacturing, and scientific research.

They are engineered to maintain stable internal conditions while minimizing heat transfer from the outside. Civil engineers play a crucial role in their foundation, insulation design, structural integrity, and installation.

Understanding how these tanks work is essential for anyone working in construction, plant design, or infrastructure development involving cryogenic storage.

Working Principle of Cryogenic Tanks

Cryogenic tanks function based on the principle of minimizing heat ingress to keep the liquefied gases stable. These tanks have a double-walled structure. The inner tank holds the cryogenic liquid, and the outer shell provides structural protection.

The space between the two walls is evacuated to create a vacuum, which significantly reduces heat transfer by conduction and convection. Despite these measures, some heat still enters the tank, causing gradual evaporation of the liquid into gas, a process known as boil-off.

To prevent pressure build-up due to this boil-off, pressure relief valves are installed. These valves automatically release excess gas, ensuring the tank operates safely. Proper insulation and relief systems are vital to reduce gas loss and maintain operational efficiency.

Types of Cryogenic Tanks

Cryogenic tanks are available in different configurations depending on the application, location, and volume requirements. Some commonly used types include:

1. Horizontal Cryogenic Tanks

These tanks are cylindrical and mounted horizontally. They are used in transportation and in sites with height restrictions.

2. Vertical Cryogenic Tanks

Mounted vertically on concrete foundations, these tanks are commonly used in industrial, hospital, and energy plant setups.

3. Portable Dewars

These are small, mobile tanks used in laboratories and medical facilities. They store small amounts of cryogenic liquids like liquid nitrogen or liquid oxygen.

4. Microbulk Tanks

Microbulk tanks serve as a middle ground between large bulk tanks and portable dewars. They are used in medical and specialty gas applications.

5. ISO Cryogenic Containers

ISO containers are standardized for global transport. They can carry liquefied gases like LNG and are suitable for intermodal transportation by road, rail, or ship.

6. Spherical Cryogenic Tanks

These tanks are used for high-pressure storage and provide uniform stress distribution. They are typically used in large LNG terminals and refineries.

7. Underground Cryogenic Tanks

Installed below the ground surface, these tanks benefit from natural insulation provided by the soil and are used in urban and defense applications.

8. LNG Bullet Tanks

These tanks are horizontally oriented and designed specifically for storing LNG in satellite regasification units.

9. Mobile Cryogenic Road Tankers

These are road-based vehicles with insulated cryogenic tanks used for transporting liquefied gases over long distances.

Each type is built with materials, insulation systems, and structural arrangements tailored to the specific cryogen and application environment.

Applications of Cryogenic Tanks

Cryogenic tanks are essential in several industries. Below are their primary areas of use:

Energy Sector

Cryogenic tanks are fundamental in storing and transporting Liquefied Natural Gas (LNG), a cleaner fuel alternative. They are also used in the storage of liquid hydrogen, which supports the growing hydrogen economy.

Healthcare

Hospitals depend on liquid oxygen stored in cryogenic tanks for respiratory support. Liquid nitrogen is used for cryotherapy, medical imaging, and biological sample preservation.

Manufacturing

Industries use cryogenic gases like liquid nitrogen and argon for welding, metal fabrication, and chemical processing. These gases are stored in cryogenic tanks to ensure a continuous and safe supply.

Research and Space Exploration

Cryogenic tanks store gases for space missions, scientific research, and advanced laboratory testing. Technologies like NASA’s Cryogenic Flux Capacitor are examples of innovations in this area.

Food and Beverage

Liquid carbon dioxide stored in cryogenic tanks is widely used for carbonation and freezing processes in the food industry.

Construction and Engineering Features

Cryogenic tanks are designed to handle high pressures, ultra-low temperatures, and seismic or wind loads. Below are their main construction features.

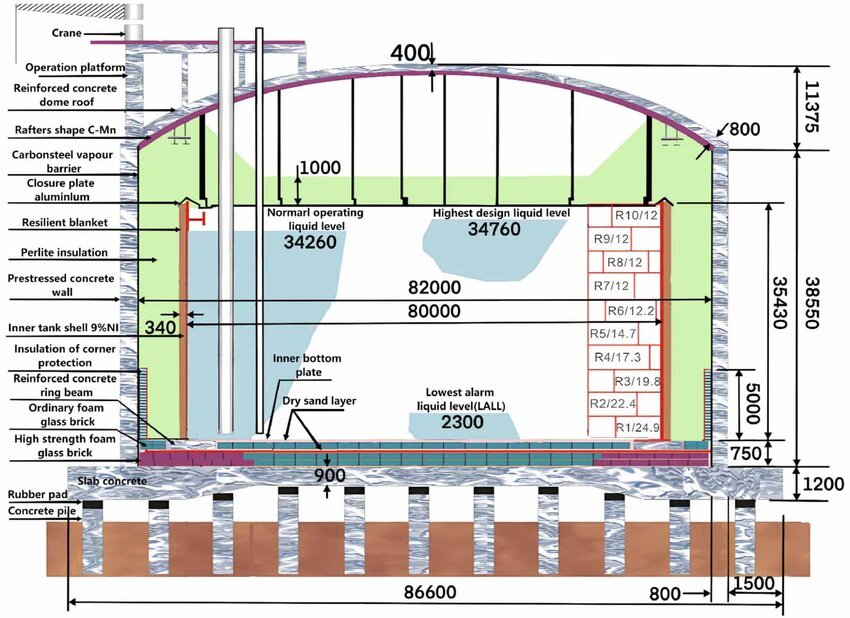

Double-Walled Design

The tank consists of an inner tank, usually made from stainless steel or 9% nickel steel, and an outer jacket made from carbon steel. The space between them is vacuum-insulated, often enhanced with multilayer insulation.

Common Insulation Materials

- Multilayer Insulation (MLI) – Thin reflective layers separated by low-conductivity spacers.

- Micro-fiberglass (Cryolite™) – Used for easy evacuation and insulation enhancement.

- Perlite Powder – Common in stationary tanks but prone to settling.

- Cellular Glass Blocks – Used in flat-bottom tanks for base insulation and load distribution.

Structural Arrangement

The inner tank is suspended within the outer shell and supported using skirts or legs to accommodate thermal expansion and contraction.

For seismic areas, tanks are designed to resist both impulsive and convective (sloshing) forces. Modern engineering tools like Finite Element Modeling (FEM) and Computational Fluid Dynamics (CFD) are used for precise design and optimization.

The foundation must support the tank’s massive weight while preventing soil freezing and heaving. Some common foundation types include:

| Foundation Type | Description |

|---|---|

| Ring Wall | Reinforced concrete ring with heaters to prevent frost |

| Slab-on-Grade | Concrete slab covering the entire tank base |

| Elevated Pile Cap | Raised slab supported by piles; avoids soil contact |

Concrete Volume Requirements

Large LNG tanks can require more than 17,500 m³ of concrete and 3,400 tonnes of rebar. The outer concrete wall can be 550mm to 800mm thick, often post-tensioned for additional strength.

Estimated Costs and Market Trends

General Cost Estimates

| Tank Type | Capacity | Estimated Cost (USD) |

|---|---|---|

| Portable Dewars | 5–50 liters | $900 – $1,500 |

| Medium Tanks | 10,000–50,000 L | $10,000 – $50,000 |

| Large LNG Tanks | 160,000 m³ | $130 million+ |

Key Cost Factors

- Material type (9% nickel, stainless steel)

- Manufacturing complexity

- Insulation system

- Size and cryogen type

- Safety features and testing

- Compliance with codes and standards

Despite high costs, the market is growing steadily. The global cryogenic tank market is expected to reach $10.77 billion by 2032, driven by energy transition, medical needs, and industrial development.

Safety and Operational Management

Critical Safety Features

- Pressure relief valves to prevent explosions

- Insulation monitoring to detect vacuum failure

- Ventilation systems to avoid oxygen-deficient or flammable atmospheres

- Secondary containment structures for spill control

Personnel working with cryogenic systems must wear:

- Safety goggles and face shields

- Loose-fitting insulated gloves

- Full-sleeved clothing and protective footwear

Cryogenic tank installations must also comply with various safety standards such as ASME BPVC, EN 13458, and NFPA 55.

Maintenance Practices

Proper operation and maintenance are essential to avoid risks and extend tank life:

- Regularly check pressure, temperature, and boil-off rates.

- Inspect for ice formation, dents, or insulation damage.

- Re-evacuate vacuum space if insulation fails.

- Clean tank exteriors using mild cleaning agents.

- Transport tanks with proper handling equipment and safety protocols.

Maintenance of cryopumps, pressure valves, and safety relief systems must be done periodically based on manufacturer guidelines.

Cryogenic tanks are high-performance systems essential for storing liquefied gases at ultra-low temperatures. Their design involves advanced insulation technologies, specialized materials, structural supports, and robust civil engineering foundations.

Civil engineers contribute significantly to cryogenic tank projects—especially in foundation design, structural analysis, and construction execution. With growing applications in clean energy, healthcare, and advanced manufacturing, these tanks are set to become even more important in the future.

Understanding cryogenic tank systems is critical for professionals working in the design and construction of industrial facilities. By mastering their principles, engineers can ensure the safety, efficiency, and durability of these essential infrastructures.

Share This Knowledge

If you’re a student or a practicing civil engineer, share this article with your peers. Use it for academic learning, project planning, or professional discussions. Understanding cryogenic tanks is no longer optional—it’s a part of the future of engineering.

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.