In this article, we explained what is development length of bar, types of bond, development length formula for Beam, column, footing, and slab, development length examples and so more.

Table of Contents

Development length of bar

In analysis and design of any R.C.C Structure, we consider that concrete & steel have perfect bond. No slippage occur between steel & concrete.

The perfect Grip between concrete & steel due to adhesion or bearing is known as Bond.

Do You Know: 5 Best Structural Design and Analysis Software

Factors Responsible for bond Strength

- Adhesion

- Frictional Resistance

- Mechanical interlock

1. Adhesion

The perfect setting of concrete is dependent on well curing of concrete.

2. Frictional Resistance

Friction is also major factor for bond strength, it’s increase the bond strength between steel & concrete.

3. Mechanical interlocking

Mechanical interlocking occur due to corrugation surface of deformed bars. Mechanical interlocking increase 20 to 25% of bond strength.

The bond strength in concrete can be increased by following method.

- Use of deformed or twisted bar.

- Use of high grade of concrete.

- Perfect compaction & curing of concrete.

- Use of bends or hooks on ends of bar.

Also Read: What is Flexural Strength of Concrete

Types of bond

- Flexural bond

- Anchorage bond

1. Flexural bond

The bond between steel & concrete in a longitudinal direction due to which steel & concrete act as a single elements is known as a flexural bond.

2. Anchorage bond

The bond between steel & concrete in a Anchorage zone of R.C.C section due to which steel can’t came out from the section is known as Anchorage Bond.

Definition of Development length

The embedded length of steel in concrete or RCC element, to transfer the design forces, is known as development length or Anchorage length of bar.

The pull out test was carried out to find development length. In which a # diameter rod was embedded in a concrete. An axial pull force is applied and increased uniformly.

Pull force (p) is noted when the bars is pulled out from concrete section.

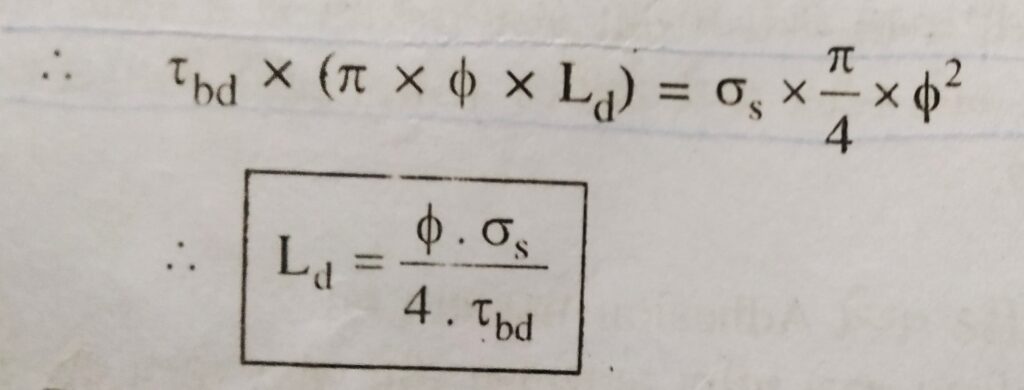

To find development length or Anchorage length of bar, the bond resistance of concrete and strength of the bar can be equated.

Strength of bar = Bond resistance of concrete

Also Read: How to find Expansion joint in Building

Bond stress

Bond stress is defined as the shear force acting longitudinally on unit surface area of bar.

Bond stress is dependent on grade of concrete.

| Grade of Concrete | Design bond stress (N/mm2) |

|---|---|

| M20 | 1.2 |

| M25 | 1.4 |

| M30 | 1.5 |

| M35 | 1.7 |

| M40 and above | 1.9 |

- For deformed bars, value of bond strength increased by 60%.

- For compression bar, value of bond stress increased by 25%.

Development length for bundled bar

In case of use of bundled bar in structural element, the total effective perimeter for a group of bars is less than the sum of perimeter of individual bars.

Therefore, the development length of each bar of bundled bars shall be increased by, 10% for two bar in contact, 20% for three bars in contact and 33% for four bars in contact for the individual bar.

Also Read: Why doubly reinforced concrete beam is less economical

Examples on Development Length

Find out the development length of the 20mm dia bar which have Fe-500 grade steel bar, provided as a compression bar of beam.

- # = 20mm

- Fy = 500 N/mm2

- Fck = 20N/mm2

Development length of bar

= (yield stress x dia of bar) / (4 x bond stress of concrete)

Yield stress = 0.87 fy

= 0.87 x 500

= 435N/mm2

Design bond stress of concrete as per IS 456, = 1.2N/mm2

The design bond stress should be increased 60% for deformed bars and 25% for compression bar.

Design bond stress = 1.2 x 1.60 x 1.25

= 2.4N/mm2

Therefore, development length of bar

= (20x 435) / (4 x 2.4)

= 906

Development length in Column

for Compression Zone

| Fck | Fy 250 | Fy 415 | Fy 500 |

|---|---|---|---|

| M20 | 31# | 32# | 39# |

| M25 | 27# | 28# | 33# |

| M30 | 25# | 26# | 31# |

| M40 | 20# | 20# | 25# |

For Tension Zone

| Fck | Fy 250 | Fy 415 | Fy 500 |

|---|---|---|---|

| M20 | 39# | 41# | 49# |

| M25 | 33# | 35# | 42# |

| M30 | 31# | 32# | 39# |

| M40 | 25# | 26# | 31# |

Development length in Beam

for Compression Zone

| Fck | Fy 250 | Fy 415 | Fy 500 |

|---|---|---|---|

| M20 | 36# | 38# | 45# |

| M25 | 31# | 32# | 39# |

| M30 | 29# | 30# | 36# |

| M40 | 23# | 24# | 29# |

for Tension Zone

| Fck | Fy 250 | Fy 415 | Fy 500 |

|---|---|---|---|

| M20 | 45# | 47# | 57# |

| M25 | 39# | 40# | 49# |

| M30 | 36# | 38# | 45# |

| M40 | 29# | 30# | 36# |

where # = Diameter of bar

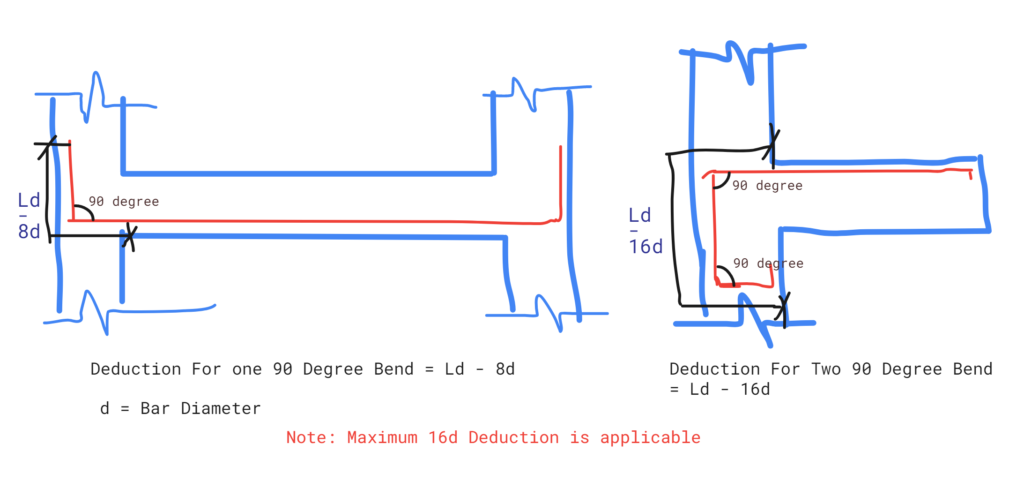

Deduction for Anchorage Length

IS 456 codes for design of RCC Structure is suggest some deduction for anchorage length of bar which is mention in clause no 26.2.2.1.

This deduction is basically dependent on the type of bends and hooks. If the bars are bend in or hooked then the bend or hook consist the some anchorage which help to make a strong bond between bar and concrete.

IS 456 Code says if the anchoring bar is subjected to 45 degree Bend then the anchorage value for band is consider the 4 times the diameter of bar that is limited to 16 times the diameter of anchoring bar.

The Anchorage value for standard U-Type hook shall be equal to 16 times diameter of bar.

I am a Professional Civil & Structural Engineer having more than 4 years of experience in Engineering, Procurement and Construction industry. Here i sharing the latest updates of EPC Projects and Construction News.