we discuss special types of repair material for building maintenance. Describe injection, patch, bonding, resurfacing and other types of repair materials.

Table of Contents

Special Types of Repair Material for Building maintenance

Hello, friend welcomes to our civil engineering community civil engineering web. In this web, we discuss special types of repair material used in building maintenance.

We detail Describe injection grout repair material, patch repair material, bonding repair material, resurfacing repair material and another type of repair material like sika building repair material.

The building repair material is described as below. In a form of List.

1. Patch repair materials:

Here we discuss types of patch repair material as per application and material.

I). Cementitious mortar/concrete :-

As per sika products, different types of cementitious repair mortar are described in below.

i) Sika Mono Top 615:-

Usage of sika mono top 615.

- For repairing all types of structures

- Overhead and vertical repairs

- Hand-applied repairs

- Spray applied repairs

- For exterior and interior use

Advantages of sika mono top 615:

- Pre-bagged for quality

- Just add water

- Sprayable by the wet spray method

- Contains no chloride admixtures

- High build

- Low wastage

ii) Sika Mono Top 612:

Usage of sika mono top 612.

- For repairing all types of structures

- Suitable for application in Marine environments

- Horizontal, vertical and overhead repairs

- Hand-applied repairs

- Spray applied repairs

- For exterior and interior use

Advantages of sika mono top 612.

- Pre bagged for quality

- Easy to mix and apply

- Low shrinkage

- Good mechanical properties

- Adjustable consistency

- Suitable for drinking water contact

iii) Sika Mono Top 412N:

Usage of sika mono top 412N.

- Suitable for restoration work. Repair damaged concrete in buildings, bridges, and other superstructure works.

- Suitable for structural strengthening.

- Suitable for preserving or restoring passivity. I

- A tested application under live dynamic loading

Advantages of sika mono top 412N.

- Sulfate resistant

- For hand or machine application

- Easy to apply

- Application up to 50 mm in 1 layer

- Very low shrinkage behavior

- Low permeability

- A1 fire rating

- Galvashield compatible

iv) Sika Mono Top 115 GP :

Usage of Sika Mono Top 115GP.

- For repairing all types of structures not exposed to water submersion.

- Overhead and vertical repairs

- Hand-applied repairs

- For exterior and interior use

Advantages of Sika Mono Top 115 GP.

- Pre-bagged for quality

- Just add water to amount required

- Contains no chloride admixtures

- High build

- Low wastage

II Polymer Modified Cementitious Mortar/Concrete

i) Meadow Patch T1:

Mewdow atch T1 is applicable for all type of local repair work. Polymer modified repair mortar is specially designed for vertical, horizontal, and overhead repair applications. This material is used for all localized repair patching and minor repair work.

III) Polymer Mortar / Concrete

Polymer mortar/concrete is a mixture of different types of binders, compounds, and aggregate which uses epoxy, polyester, polymer resin bonds and vinyl ester.

Polymer mortar/cement is provided better corrosion resistance compared to conventional construction material like Portlandcement mortar.

Polymer concrete is a mixture of polymer cement, water coarse aggregate, and fine aggregate. Where,

Polymer mortar is a mixture of polymer binders, water, and fine aggregate.

Uses:-

- Uses as corrosion resistance mortar/concrete.

- Use for join components and form structure

- Used for fill medium cracks

- Polymer mortar is used as filler and sealants.

- Polymer mortar some time used as the material of gunnite/shotcrete purpose.

IV) Quick setting compounds

V) High alumina a cementbased

VI) Calcium sulfate based

VII) Magnesium phosphate based Patch.

Magnesium phosphate cement mortars have superior bond strength compare to `

Cementitious grout is suitable for a range of different bedding and fixing applications. These include bases, bearing plates and steel frames.

Most brands have a selection of grouts formulated for different applications, with a focus on certain attributes such as high strength or non-shrink.

2. Injection Grouts:

i) Cementitious grout:

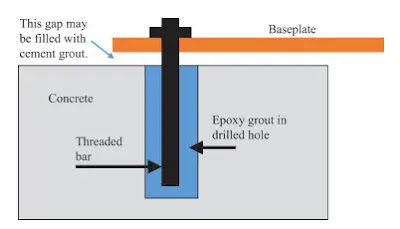

Cementitious grout is utilized to make a solid bearing surface between structural baseplates and base foundations. It enables even dispersal of the load into the existing concrete slab. The grout will assist in transferring the overall load of the column into the concrete foundation.

Cementitious grout is suitable for a range of different bedding and fixing applications. These include bases, bearing plates and steel frames.

Most brands have a selection of grouts formulated for different applications, with a focus on certain attributes such as high strength or non-shrink.

Cementitious grouts product as per IndiaMART.

Specification:

- It is cement and polymer modified joint filler

- It effectively fills the gaps and levels itself to give a hard-wearing and non dusting tile joints

- It firmly holds the tiles together to give along life to the tiles

- Available in more than 27 shades

- Pack Size: 1 Kg Pouch/10 Kg Pouch

Applications:

- Perfect filling & finishing of tile joints of ceramic

- Marble & Vitrified tiles up to a width of 6 mm

Advantages:

- Available in wide range colors matching of appropriate shade to the color of the tile is feasible.

- Has strong bonding property & high abrasion resistance. Joint to do not wear out & remain in place

- Non Fading colors

- Low Shrinkage

ii) Polymer grouts:

Polymer grouts are made in a similar way like cementitious grouts, But the cement is replaced with polymer cement. such polymer are Epoxy, polystyrene and so more.

Polymer grouts similar to cementitious grouts, therefore the application of polymer grouts is very similar to cementitious grouts.

But Polymer grouts are more expensive and have far greater bond strength compare to cementitious grouts. Polymer grouts are normally used in applications where far lower quantities are required Like the feeling of Tiles gaps.

Here we share some product of polymer grouts.

Ardex endura cement polymer grout:

Ardex endures cement polymer grout has a great water-resistant. This polymer grout is specially designed for glazed wall tiles, porcelain tiles, mosaic tiles, vitrified tiles, and other tiles.

Features:-

- Good bond strength

- Water resistant

- For interior & exterior use

- Ardex endura Cement Polymer Grout is Suitable for joint width of 1 – 6 mm

ii) Gas forming grouts:

The gas-forming injection grout is utilized depending on the principle that the gas bubbles expand the grout to compensate shrinkage of grout after application. These gas bubbles are generated on the reaction of some ingredients (usually Aluminium and Carbon the powder contained in grout) with the cement liquor.

This type of gas-forming grouts are temperature-sensitive and isn’t suitable for high-temperature applications. but if used in the high-temperature applications that require proper confinement to develop strength and volume stability because the reaction forming gas bubbles could also be too fast and should complete before placing the grout.

iv) Sulpho-aluminate grouts

Sulpho-aluminate grouts are also one special type of injection grout. It also depends on the principal of the shrinkage compensation.

Sulpho-aluminate grouts is that type of grout which is expanding after the grout, and it is more reliable to gas-forming grouts.

But the expansion of Sulpho-aluminate grouts requires post-hardening curing and it is effective when moist curing is available. But if moist curing is not available then this is not effective.

3. Bonding materials:

i) Polymer emulsion type

polymer emulsion is utilized in a large range of applications like adhesives, inks, paints, coatings, drug delivery systems, gloves, floor polish, films, and cosmetics.

ii) Polymer resin type

4. Resurfacing materials:

- Protective coatings and membranes

- Impregnants and hydrophobic agents

- Overlays

- Toppings /screeds

- Gunite /shotcrete

- Sealing materials

- Waterproofing material

5. Other Repair materials

- Corrosion inhibitors

- Rebar protective coatings

- Cathodic protection

- Realkalization

ALSO READ :-

TOP 8 INDIA’S BEST GREEN BUILDING AS PER LEED AND GRIHA