What is Polymer Concrete and Sulphur Infiltrated Concrete, Types, Application?

In this web, we share the Detailed Study of Polymer concrete and Sulphur Infiltrated Concrete. It’s types like PIC, PCC, PC. Its application uses and how to make polymer concrete and sulphur infiltrated concrete. Also, describe which type of polymer used in concrete.

Table of Contents

What is Polymer Concrete:

When polymer substances are inserted in ordinary concrete, obtain concrete is called as polymer concrete. Normal concrete has porosity so its strength is low. Adding a polymer or a monomer into ordinary concrete, due to reduces its porosity and increases its strength.

Types of Polymer Concrete:-

There are four types of polymer concrete:

- Polymer Impregnated Concrete (PIC)

- Polymer Cement Concrete (PCC)

- Polymer Concrete (PC)

- Partially impregnated and surface coated polymer concrete

1. Polymer Impregnated Concrete (PIC):

This type of concrete is the most widely used polymer concrete. In which ordinary concrete is cured and dried in the oven. Then after The air is removed from it by vacuum in an open cell. Then Polymerization is done by radiation or heat, using a low viscosity monomer.

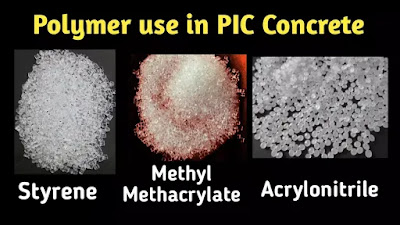

Different types of polymers used in this type of concrete is given below.

- styrene

- t – butyl Styrene

- Methyl methacrylate (MMA)

- Acrylonitrile etc.

The monomer can also be inserted by dipping the specimen into the monomer at the proper time. Once removed Specimen from their monomer, It’s should be covered with a plastic seat so that the monomer does not evaporate.

Also Read: What is Autoclaved Aerated Concrete

Uses of Polymer Impregnated Concrete:-

- For impregnation of bridge decks.

- For Irrigation Construction such as Dams, Canals, Weir, Barrage, etc.

- For Structural Members

- For Marine construction and Underwater Construction

- For the repair Works of construction.

Properties of Polymer-Impregnated Concrete:

Properties of polymer-Impregnated concrete is explain in Comparison.

Comparison Between Polymer-Impregnated concrete and Concrete Without Impregnation.

1. Polymer-Impregnated concrete:

- Compressive Strength:- 130MPa

- Tensile Strength:- 11.5MPa

- Flexural Strength:- 18.5MPa

- Elastic Strength:- 45MGPa

2. Concrete Without Impregnation.

- Compressive Strength:- 40MPa

- Tensile Strength:- 3.0MPa

- Flexural Strength:- 5.2MPa

- Elastic Strength:- 25MGPa

2. Polymer Cement Concrete (PCC):

Polymer CementConcrete is prepared from a mixture of cement, aggregate, water, and monomer. The mixture is cast in the mould then cured, dry, and polymerized.

Also Read: Different Types of Partition Wall

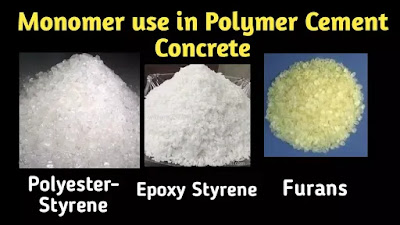

The monomers used in Polymer Cement Concrete are as follows.

- Polyester – Styrene

- Epoxy Styrene

- Furans

- Vinylidene Chloride

Uses of Polymer Cement Concrete:

- Flooring of food processing and chemical industries.

- Water resistant floors

- Decks over steel bridges

- Repair of sea defense structures.

3. Polymer Concrete (Resin Concrete):

- Polymer is used instead of cement as a binder in concrete.

- Polymer or Monomer is Mix with Aggregate by hand or by machine.

- Then it is molded or cast in Wooden box (Farma) or Steel Box (steel Farma) as per required shape.

- Mould realizing agent is spread on formwork (box) due to that The formwork does not stick to the concrete and can be easily separated.

- Polymer strictly attached with aggregate and make hardened polymer concrete. This process is called polymerization.

- Accelerators are added to speed up the process.

- Aggregates to be used in concrete should be dry. Because the polymerization process does not occur in wet aggregate.

Polymer are given below which are used in process.

- Methyl methacrylate

- Polyester string

- Epoxy string

- Urea formaldehyde

- Phenol formaldehyde, Etc.

Uses of Polymer Concrete or Resin concrete:

- Repair of overlays, Air field pavements

- Concrete pipes

- high voltage insulator

Sulphur Infiltrated Concrete:

In the past Attempts have been made to use sulphur instead of cement as a binding material. Sulphur is heated and melted then mix with coarse aggregate and fine aggregate and prepare concrete. This concrete gives good strength when cooled. It has good resistance against acid and chemical, but such concrete is more costly than ordinary cement concrete.

Modern studies show that lean porous concrete, Sulphur is forcefully added into concrete which is increase the strength of concrete and improved the properties of concrete. Approximately 100MPa strength obtained in just 2 days. By adding sulphur in lean porous concrete is reduce the sulphur amount in concrete and make economical concrete.

Less than 100mm size coarse aggregate, Well graded fine aggregate and 99.9% purified sulphur used in this process.

Water/cement ratio kept 0.7 or more.

Two methods are adopted for making Sulphur Infiltrated Concrete.

Method-1

- In this test the specimen is dried at 121°C in a heating cabinet for 24 hours after 24 hours of wet Curing.

- Then after the dry test samples are kept in a sulphur molten container at a temperature of 121°C for 3 hours.

- Then after remove the samples from the container, wipe the sulphur from the surface and keep specimen for cool at room the temperature for 1 hour.

- Then after The specimens weighed, From which the weight of the entering sulphur is obtained.

Method -2

- In this Method The specimen of dry concrete is placed in an airtight container with a vacuum pressure of 2 mm mercury and kept for 2 hours.

- Then after the vacuum is removed, the specimen are immersed in the molten Sulphur for half an hour.

- Then after the specimen are taken out, the sulphur wiped off the surface, and allowed to cool at room temperature.

During testing, the compressive strength of sulphur infiltrated concrete increases by 7 times and the tensile strength increase by 5 times.

Such concrete has,

- High resistance to freezing and thawing.

- Corrosion resistance is high.

- Permeability decreases of concrete.

Uses of Sulphur Infiltrated Concrete:

- For making Precast roof elements, fencing posts, pig pipes

- For making Railway sleeper

- In industries where high corrosion resistance is required.

- Precast concrete is cheaper than commercial concrete.

Also Read: How Many Types Of Chemical Admixture Used in Concrete

What are the Applications of Sulphur Infiltrated Concrete?

The various applications of sulphur infiltrated concrete are listed here.

1. Sulphur infiltrated concrete was used for making of precast roof elements, fencing posts, pig pipes, etc.

2. Sulphur infiltrated concrete was used for making of railway sleepers.

3. It is used where high corrosion resistance is required.

What is the density for sulphur infiltrated concrete in kg/m3?

The density of sulphur infiltrated concrete is varies from 2200 kg/m3 to 2400 kg/m3.

What are the main components of Sulphur infiltrated concrete?

The main components of sulphur infiltrated concrete are listed here.

1. Sulphur

2. Fine Aggregate

3. Coarse Aggregate

Hi,

is it possible to send me the complete articles/publications that you have available on Sulphur Concrete, please ? THANK YOU !