Table of Contents

REUSE OF FLYASH AND ITS UTILIZATION AT VARIOUS SECTOR

The fly ash or flue ash is also known as pulverized flue ash in the UK, the fly ash is a fine material which is generated from the burning of fuel or other material. The fly ash is waste material. Normally 65% of overall fly ash is generated by thermal power stations. Generally in the past the fly ash is used in the disposal of the landfill. But due to recent researches and new advancements which make different uses of waste fly ash in various sectors. Using fly ash in construction work, the construction made eco friendly.

Also Read: What is Zero Energy Building

DIFFERENT REUSES OF WASTE FLYASH OR UTILIZATION OF FLYASH IN DIFFERENT SECTOR:-

Utilization Of Flyash In Building Material:-

|

| FLY ASH |

Fly Ash Bricks Or Blocks :-

|

| FLY ASH BRICK |

The fly ash bricks is the best to reuse of waste flyash. In a fly ash bricks or block the generally 40-70% fly ash use. And other ingredient are use in fly ash bricks are lime, gypsum/cement, sand, stone dust etc. The minimum compressive strength of this block is 70kg/cm2 and maximum compressive strength achieve 250kg/cm2.

Also Read: Plastic Road in India

Portland Pozzolana Cement:-

|

| FLY ASH CEMENT |

The Portland pozzolana cement consist some amount of fly ash. In this cement the flyash content is similar to 30-40%. Due to adding of flyash, flyash improve durability, strength, and other characteristics of concrete.

Cellular light weight concrete block :-

|

| FLY ASH CONCRETE BLOCK |

These light weight concrete blocks in building with density varying from 800 kg/m3to 1800 kg/m3. The normal constituents of this Foaming Agent based technology from Germany are cement, Fly Ash (to the extent 1/4th to 1/3rd of total materials constituent), sand, water and foam (generated from biodegradable foaming agent). For the using of walling & roofing panels can also be manufacture. Foaming agent and there for the Foam generator, if used for production of CLC with over 25% fly ash content invites concession on import duty by Govt. of India.

Also Read: What Is Self Healing Concrete

Ready mix fly ash concrete :-

|

| FLY ASH CONCRETE |

Only recently its application has started growing at a quick rate. On an average 20% Fly ash (of cementitious material) in the country is being used which can easily go very high. In ready mix concrete the concrete is made by machine and use software for gradation of material which allow various ingredients and quality parameters are strictly maintained/controlled which is not possible in the concrete produced at site and hence it can accommodate still higher quantity of fly ash.

Fly ash use in embankment:-

|

| FLY ASH EMBANKEMENT |

Fly ash is somewhat of a unique engineering material. When dry, fly ash is cohesionless and considered by many as a dusty nuisance. When saturated, fly ash becomes an unmanageable mess. But, as with most fine-grained soils, fly ash can be easily handled and compacted at more intermediate moisture contents, and does exhibit some cohesion

Nearly all of the fly ash used for embankment construction is anthracite or bituminous coal fly ash. Lignite or subbituminous fly ashes, which are usually self-cementing, can harden prematurely when moisture is added, resulting in potential handling problems and inability to achieve the required degree of compaction. Fly ash use as a structural fill or embankment material was pioneered during the 1950’s in Great Britain, where it is still bid as an alternate borrow material on roadway fill projects in areas where it is available.

Also Read: GIFT City in Gujarat

Utilization Of Flyash In Agriculture Sector :-

Fly Ash is alkaline and as such improves soil quality. In fact, Fly Ash consists of all elements present in soil except organic carbon and nitrogen. Adding of fly ash in which improve soil quality. it is found that with dose of 10 MT Fly Ash per hectare and just 50% dose of chemical fertilizers (as annually required) there is increase of 20% yield in terms of grain and fodder. Fly Ash also maintains porous structure of soil and provides micronutrients. Presence of micro and macro constituents like Potassium, Boron, Calcium, Zinc etc. improves the fertility of soil. The use of fly ash in soil which also reduce the fertilizer quantity in farm for making good soil for the agriculture. Due to its alkaline behaviour it also maintain the pH of soil.

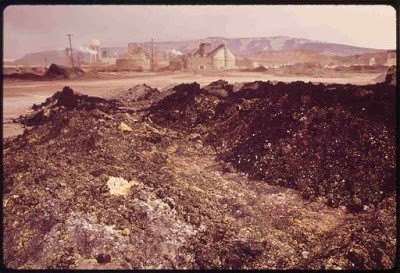

Utilization Of Fly Ash In Mine Fills :-

The fly ash is very useful for filling the mines. Due to using of fly ash for filling mines which helps to reduce use of sand and also increase the coal recovery of mines.

ADVANTAGES OF UTILIZATION OF FLY ASH :-

· Due to the increasing of fly ash utilization which reduce the space of disposal.

· Due to increasing of fly ash utilization, saving of scare of natural resources.

· Utilization of fly ash in concrete which make environment friendly concrete and reduce uses of Portland cement.

· The use of flyash in cement, reduce the heat of hydration.

· The fly also use as admixture.

· The fly ash also reduce concrete cracks problems.

· Increase workability of concrete.

DISADVANTAGE OF FLY ASH :-

· Longer settings time consumption.

· Slower strength gain

· Seasonal limitation.

· Colour variability.

· Increasing need of air entering agent.